×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Camry Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Brake Calipers found

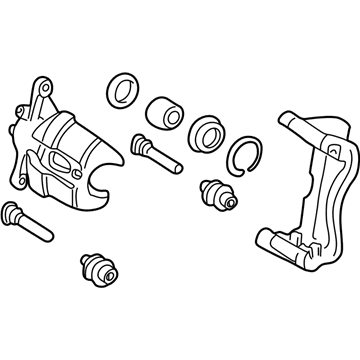

2000 Toyota Camry Cylinder Assembly, Disc

Part Number: 47750-06040-84$70.52 MSRP: $97.41You Save: $26.89 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: CYLINDER ASSY, DISC

- Position: Driver Side

- Condition: New

- SKU: 47750-06040-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Cylinder Assembly, Disc

Part Number: 47730-06040-84$70.52 MSRP: $97.41You Save: $26.89 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: CYLINDER ASSY, DISC

- Position: Passenger Side

- Condition: New

- SKU: 47730-06040-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Caliper, Driver Side

Part Number: 47750-33111$263.39 MSRP: $376.07You Save: $112.68 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Manufacturer Note: W(14 INCHES DISC WHEEL)

- Position: Driver Side

- Replaces: 47750-33110

- Part Name Code: 47750

- Item Weight: 11.70 Pounds

- Item Dimensions: 10.5 x 8.0 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-33111

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Caliper, Passenger Side

Part Number: 47730-33111$263.39 MSRP: $376.07You Save: $112.68 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Manufacturer Note: W(14 INCHES DISC WHEEL)

- Position: Passenger Side

- Replaces: 47730-33110

- Part Name Code: 47730

- Item Weight: 11.30 Pounds

- Item Dimensions: 10.6 x 7.7 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-33111

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Caliper, Driver Side

Part Number: 47750-06030$258.23 MSRP: $368.69You Save: $110.46 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Position: Driver Side

- Part Name Code: 47750

- Item Weight: 11.60 Pounds

- Item Dimensions: 10.2 x 8.1 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-06030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Caliper, Passenger Side

Part Number: 47730-06030$258.13 MSRP: $368.55You Save: $110.42 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Part Name Code: 47730

- Item Weight: 12.20 Pounds

- Item Dimensions: 9.9 x 7.8 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-06030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

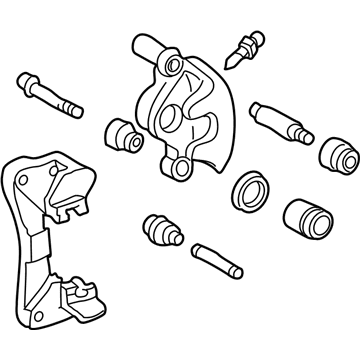

2000 Toyota Camry Caliper, Rear Driver Side

Part Number: 47750-33160$244.64 MSRP: $349.29You Save: $104.65 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Rear Left; Cylinder Assembly, Disc Brake, Rear Driver Side; Brake Caliper

- Position: Rear Driver Side

- Part Name Code: 47750A

- Item Weight: 5.50 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-33160

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Cylinder Assembly, Rear Disc Brake, Passenger Side

Part Number: 47730-33160$244.64 MSRP: $349.29You Save: $104.65 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Brake Caliper

- Position: Passenger Side

- Part Name Code: 47730B

- Item Weight: 5.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-33160

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Caliper, Rear Driver Side

Part Number: 47750-06060$235.83 MSRP: $336.71You Save: $100.88 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Rear Left; Cylinder Assembly, Disc Brake, Rear Driver Side; Brake Caliper

- Position: Rear Driver Side

- Part Name Code: 47750A

- Item Weight: 5.90 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-06060

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Position: Driver Side

- Replaces: 47750-06050

- Part Name Code: 47750

- Item Weight: 11.30 Pounds

- Item Dimensions: 9.9 x 7.5 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-08010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Replaces: 47730-06050

- Part Name Code: 47730

- Item Weight: 12.30 Pounds

- Item Dimensions: 10.1 x 7.7 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-08010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Rear Right; Cylinder Assembly, Rear Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Part Name Code: 47730B

- Item Weight: 6.10 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-06060

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Position: Driver Side

- Part Name Code: 47750

- Item Weight: 12.30 Pounds

- Item Dimensions: 10.5 x 8.0 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-33181

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Part Name Code: 47730

- Item Weight: 11.60 Pounds

- Item Dimensions: 10.7 x 7.9 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-33181

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Brake Caliper

Looking for affordable OEM 2000 Toyota Camry Brake Caliper? Explore our comprehensive catalogue of genuine 2000 Toyota Camry Brake Caliper. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

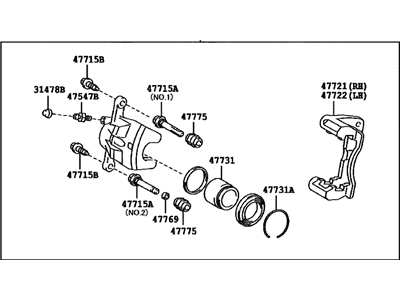

2000 Toyota Camry Brake Caliper Parts Q&A

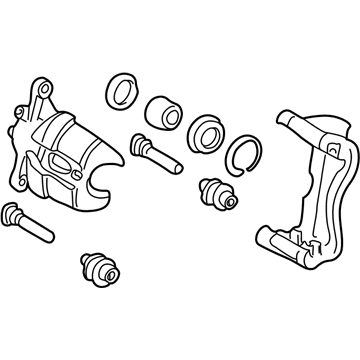

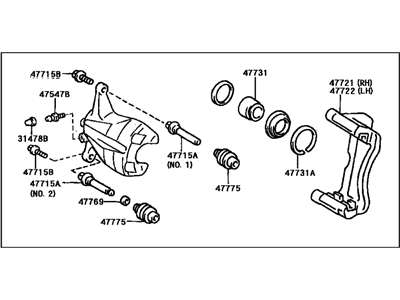

- Q: How to Effectively Service and Repair a Brake Caliper on 2000 Toyota Camry?A: Start brake caliper service and repair operations by using a screwdriver to eliminate the set ring and cylinder boot. Start by placing a cloth between the caliper and the piston before proceeding with compressed air to remove the piston while avoiding placing fingers in front of it. Start by removing the piston seal with a screwdriver and then removing both the sliding pins from the torque plate. During the reassembly process align the sliding pin with sliding bushing at the bottom side of the CAFE engine while placing it at the top side of the 1MZ-FE engine. The installation process requires a 22 mm socket wrench for 5S-FE engines and a 24 mm socket wrench for 1MZ-FE engines to secure new dust boots with proper placement of the metal plate within the torque plate. Inspection of the pad lining requires a ruler for measuring thickness where the standard thickness stands at 12.0 mm for 5S-FE engines and 11.0 mm for 1MZ-FE engines with a minimum acceptable thickness of 1.0 mm; pad replacement should occur when the minimum threshold is met or exceeded by wear or degradation. Use a micrometer to measure disc thickness and change or grind the disc when it reaches below 26.0 mm minimum standard or shows severe scoring. A dial indicator set 10 mm from the outer edge should measure disc runout for a maximum acceptable value of 0.05 mm yet exceeding this value requires checking bearing play and axle hub runout by adjusting or grinding the disc. It is possible to adjust disc runout by first removing the torque plate and hub nuts and disc. Then install the disc after rotating it one-fifth of its original position before tightening the hub nuts to 103 Nm. Rinse the other hub positions with the same procedure and keep the disc that displays the minimum measurement below 0.05 mm in position as a replacement; otherwise, install a new disc first. Finally install the torque plate before tightening the mounting bolts to 107 Nm and coat specified parts with lithium soap base glycol grease throughout the reassembly process.