×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota RAV4 Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Differentials found

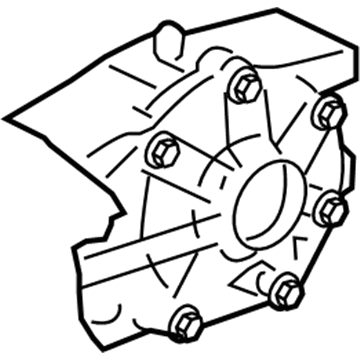

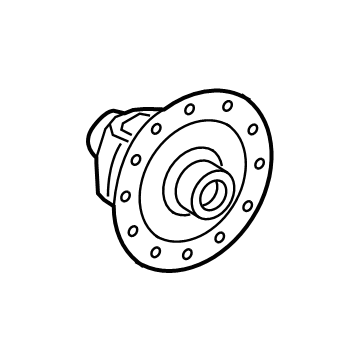

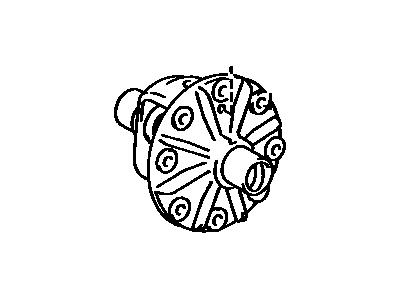

Toyota RAV4 Differential Carrier

Part Number: 41110-42042$811.42 MSRP: $1189.15You Save: $377.73 (32%)Ships in 1-3 Business DaysToyota RAV4 Differential Assembly, Rear

Part Number: 41110-42020$3535.31 MSRP: $5181.04You Save: $1645.73 (32%)Ships in 1-3 Business DaysToyota RAV4 Case Sub-Assembly, Rear Differential

Part Number: 41301-52100$376.35 MSRP: $551.55You Save: $175.20 (32%)Ships in 1-3 Business DaysToyota RAV4 Case Sub-Assembly, Rear Differential

Part Number: 41301-48020$1866.87 MSRP: $2735.92You Save: $869.05 (32%)Ships in 1-3 Business DaysToyota RAV4 Case

Part Number: 41301-42060$1901.86 MSRP: $2787.21You Save: $885.35 (32%)Ships in 1-3 Business DaysToyota RAV4 Differential Carrier, Rear

Part Number: 41110-42060$928.42 MSRP: $1360.61You Save: $432.19 (32%)Ships in 1-3 Business DaysToyota RAV4 Differential Assembly, Rear

Part Number: 41110-42054$1774.67 MSRP: $2600.81You Save: $826.14 (32%)Ships in 1-2 Business DaysToyota RAV4 Differential Assembly, Rear

Part Number: 41110-42011$1706.80 MSRP: $2501.35You Save: $794.55 (32%)Ships in 1-3 Business Days

Toyota RAV4 Differential

Choose genuine Differential that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Differential for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 Differential Parts and Q&A

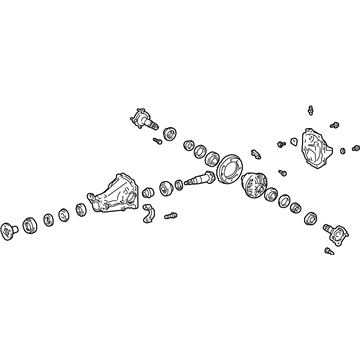

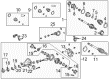

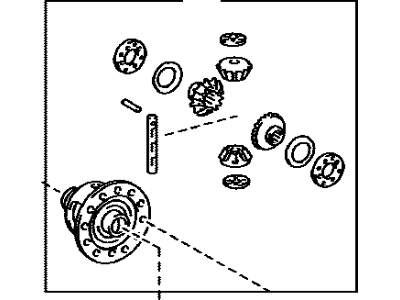

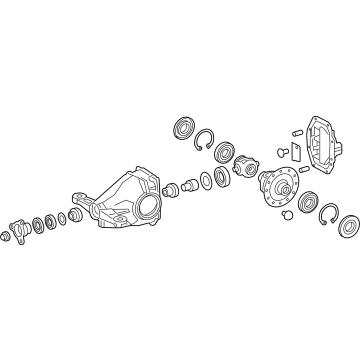

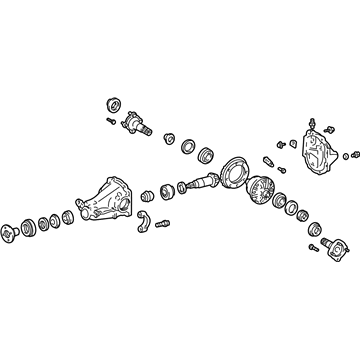

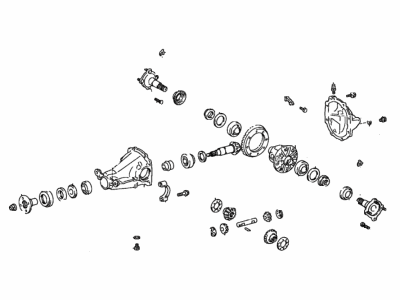

- Q: How to disassemble and reassemble the differential case on Toyota RAV4?A:Start differential case disassembly by removing the tapered roller bearing from the vehicle speed sensor drive gear side through the use of Special Service Tool: 09950-00020, 09950-00030, 09950-40011 (09957-04010), 09950-60010 (09951-00530). Confirm that the claw is firmly positioned on the bearing inner race before uninstalling the vehicle speed sensor drive gear. First mark the ring gear and differential case for alignment then disconnect the 16 bolts by applying copper hammer blows to the ring gear. To remove the tapered roller bearing from the ring gear side use Special Service Tool: 09950-00020, 09950-00030, 09950-40011 (09957-04010), 09950-00010 (09951-00450) by setting the claw at the indented position against the bearing inner race. Measure side gear backlash with a dial indicator then verify that measurement stays between 0.0020 and 0.0079 inches (0.05 - 0.20 mm); if necessary replace the thrust washer with the correct one. You should start by removing the differential case's straight pin using a pin punch and hammer motion before extracting the pinion shaft followed by the 2 pinions and all side gears with their respective 4 thrust washers from each gear segment. Replace the oil seal by using a screwdriver and hammer and press in the new tapered roller bearing outer race with Special Service Tool: 09316-60011 (09316-00011, 09316-00041) on the transmission case side. The replacement procedure requires customers to use Special Service Tool: 09316-60010 (09316-00011, 09316-00031) for driving in a new oil seal to a depth of 3.5 plus or minus 0.5 mm (0.138 plus or minus 0.020 inch). During this process, customers must apply MP grease to the lip of the oil seal. On the transaxle case side, drive out the oil seal, remove the tapered roller bearing outer race with Special Service Tool: 09316-60011 (09316-00011, 09316-00021), and reinstall the oil baffle, ensuring the projection fits into the case side cutout before pressing in a new tapered roller bearing outer race with Special Service Tool: 09950-60020 (09951-00890), 09950-70010 (09951-00150) and driving in a new oil seal to a depth of 0 - 0.5 mm (0 - 0.020 inch), also coating the oil seal lip with MP grease. Before moving ahead with assembly apply gear oil on all sliding and rotating surfaces and install appropriate thrust washers and side gears before checking the backlash for compliance with specifications and place in the pinion shaft afterward another side gear backlash inspection. Using a straight pin you should drive and caulk each differential case hole. Wipe down the differential case contact surface and heat the ring gear in boiling water and immediately install it after all moisture evaporates while aligning matchmarks and installing the 16 set bolts loosely until the ring gear cools enough to tighten them to 106 Nm (1,080 kgf-cm, 78 ft. lbs.). Use Special Service Tool: 09316-60011 (09316-00011) to install the tapered roller bearing on the ring gear side. During installation keep the outer race of the tapered roller bearing present. Installation of the vehicle speed sensor drive gear begins with putting the gear into its correct position before using Special Service Tool: 09316-20011, 09316-60011 (09316-00011) to place the new tapered roller bearing correctly. Finally, inspect the differential tapered roller bearing preload by installing the differential case assembly to the transaxle case, securing the transmission case with 17 bolts torqued to 29 Nm (300 kgf-cm, 22 ft. lbs.), and using Special Service Tool: 09564-32011 to measure the preload, which should be 0.8 - 1.6 Nm (8 - 16 kgf-cm, 6.9 - 13.9 inch lbs.) for new bearings or 0.5 - 1.0 Nm (5 - 10 kgf-cm, 4.3 - 8.7 inch lbs.) for reused bearings; if not within specification, adjust by selecting an appropriate shim before removing the transmission case side outer race and the differential case assembly.