×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota RAV4 Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Differentials found

2003 Toyota RAV4 Case Sub-Assembly, Rear Differential

Part Number: 41301-48020$1866.87 MSRP: $2735.92You Save: $869.05 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Case Sub-Assembly, Differential; Differential

- Part Name Code: 41301

- Item Weight: 6.50 Pounds

- Item Dimensions: 7.4 x 7.1 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41301-48020

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

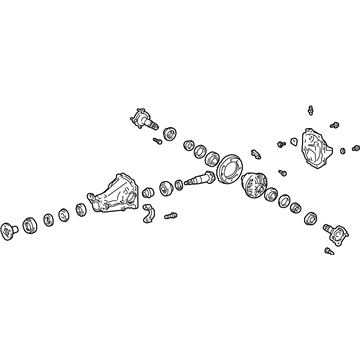

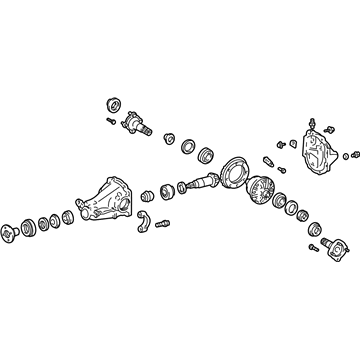

2003 Toyota RAV4 Differential Assembly, Rear

Part Number: 41110-42011$1706.80 MSRP: $2501.35You Save: $794.55 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier Assembly, Differential; Drive Axle Assembly, Rear; Carrier; Carrier Assembly, Differential, Rear; Differential

- Manufacturer Note: *FGR=41:14=2.928

- Position: Rear

- Part Name Code: 41110

- Item Weight: 77.30 Pounds

- Item Dimensions: 29.3 x 25.6 x 18.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41110-42011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota RAV4 Differential Case

Part Number: 41311-14031$291.60 MSRP: $416.34You Save: $124.74 (30%)Product Specifications- Other Name: Case, Differential; Case; Case Sub-Assembly, Rear Differential; Case, Front Differential; Case, Rear Differential; Differential

- Replaces: 41311-14030

- Item Weight: 6.20 Pounds

- Item Dimensions: 6.8 x 6.7 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41311-14031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Carrier Assembly, Differential; Drive Axle Assembly, Rear; Carrier; Carrier Assembly, Differential, Rear; Differential

- Manufacturer Note: *FGR=41:14=2.928,W(LSD)

- Position: Rear

- Replaces: 41110-42030

- Part Name Code: 41110

- Item Weight: 78.00 Pounds

- Item Dimensions: 30.4 x 25.9 x 18.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41110-42031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota RAV4 Differential

Looking for affordable OEM 2003 Toyota RAV4 Differential? Explore our comprehensive catalogue of genuine 2003 Toyota RAV4 Differential. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota RAV4 Differential Parts Q&A

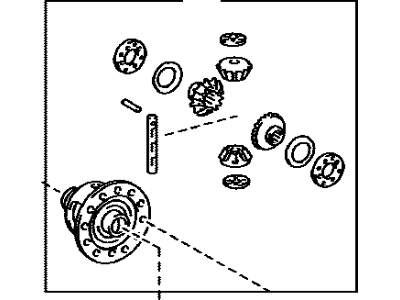

- Q: How to disassemble the differential on 2003 Toyota RAV4?A: The differential disassembly requires placing matchmarks on the ring gear and differential case and removing 1 bolts to free the ring gear with a plastic hammer strike. Apply the tapered roller bearing removal tools listed as 09950-00020, 09950-00030, 09950-60010 (09951-00480, 09951-00500) to extract the bearing that supports the FR speedometer drive gear and RR. The pin punch method using a hammer must drive the pin out from the ring gear side before removing the differential pinion shaft and all associated components including 2 differential pinions, 2 differential side gears, 2 differential pinion thrust washers and 2 differential side gear thrust washers. The side bearing outer race of the transaxle housing must be removed using a brass bar and hammer while the transaxle housing oil seal requires Special Service Tools 09649-17010, 09950-70010 (09951-07100) alongside a hammer before moving on to the oil seal of the transaxle case with Special Service Tool: 09308-00010. To install the side bearing outer race of the transaxle case begin by placing the shim followed by pressing in a new outer race with Special Service Tool: 09950-60020 (09951-00790), 09950-70010 (09951-07150) and a press while using a hammer. Before assembling the differential case, apply ATF to all thrust washers and pinion gears and side gears before you place the components inside the differential case. The alignment of pinion shaft lock pin holes should be maintained. During measurements of side gear backlash using one pinion gear that approaches the case the value should stay between 0.05 - 0.20 mm (0.0020 - 0.0079 inch) to determine the need for thrust washers. Drive the pin through the case and pinion shaft before staking the differential case then install the tapered roller bearing RR and speedometer drive gear by using Special Service Tool: 09316-20011, 09649-17010, and a press. Determine proper side bearing preload through these steps: thoroughly clean all surfaces, connect the differential to the transaxle case and use the specified torque values when tightening Bolt A to 22 Nm (224 kgf-cm, 16 ft. lbs.) then Bolts B and C to 29.4 Nm (300 kgf-cm, 22 ft. lbs.). Use Special Service Tool: 09564-32011 to rotate the differential while measuring preload which must remain between the parameters designated for new and used bearings. To make adjustments remove the differential and transaxle housing before installing the ring gear by cleaning the contact surface and heating the ring gear in water for 15 minutes then driving it with 1 bolts reaching 95.1 Nm (970 kgf-cm, 70 ft. lbs.) torque. To install the transaxle case oil seal and transaxle housing oil seal use the tools Special Service Tools: 09649-17010 and 09608-10010, 09950-70010 (09951-07150). Coating all seal lips with MP grease before installation.