×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2005 Toyota RAV4 Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Differentials found

2005 Toyota RAV4 Case Sub-Assembly, Rear Differential

Part Number: 41301-48020$1866.87 MSRP: $2735.92You Save: $869.05 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Case Sub-Assembly, Differential; Differential

- Part Name Code: 41301

- Item Weight: 6.50 Pounds

- Item Dimensions: 7.4 x 7.1 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41301-48020

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

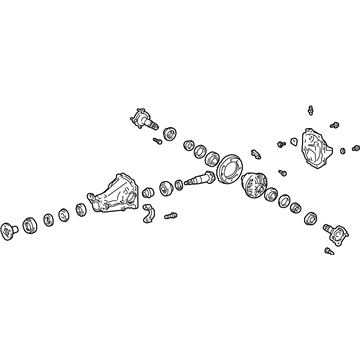

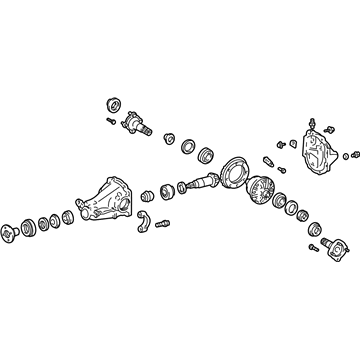

2005 Toyota RAV4 Differential Assembly, Rear

Part Number: 41110-42011$1706.80 MSRP: $2501.35You Save: $794.55 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier Assembly, Differential; Drive Axle Assembly, Rear; Carrier; Carrier Assembly, Differential, Rear; Differential

- Manufacturer Note: *FGR=41:14=2.928

- Position: Rear

- Part Name Code: 41110

- Item Weight: 77.30 Pounds

- Item Dimensions: 29.3 x 25.6 x 18.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41110-42011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota RAV4 Differential Case

Part Number: 41311-14031$291.60 MSRP: $416.34You Save: $124.74 (30%)Product Specifications- Other Name: Case, Differential; Case; Case Sub-Assembly, Rear Differential; Case, Front Differential; Case, Rear Differential; Differential

- Replaces: 41311-14030

- Item Weight: 6.20 Pounds

- Item Dimensions: 6.8 x 6.7 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41311-14031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Carrier Assembly, Differential; Drive Axle Assembly, Rear; Carrier; Carrier Assembly, Differential, Rear; Differential

- Manufacturer Note: *FGR=41:14=2.928,W(LSD)

- Position: Rear

- Replaces: 41110-42030

- Part Name Code: 41110

- Item Weight: 78.00 Pounds

- Item Dimensions: 30.4 x 25.9 x 18.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 41110-42031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota RAV4 Differential

Looking for affordable OEM 2005 Toyota RAV4 Differential? Explore our comprehensive catalogue of genuine 2005 Toyota RAV4 Differential. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2005 Toyota RAV4 Differential Parts Q&A

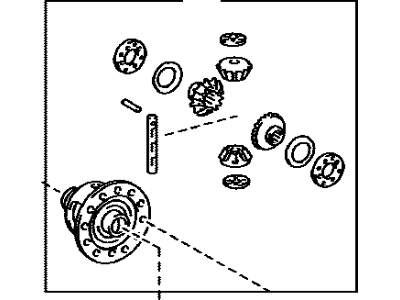

- Q: How to disassemble and reassemble the differential case on 2005 Toyota RAV4?A: The procedure to disassemble the differential case starts with removing the tapered roller bearing from the vehicle speed sensor drive gear side using Special Service Tools: 09950-00020, 09950-00030, 09950-40011 (09957-04010) and 09950-60010 (09951-00530). A proper claw placement on the bearing inner race must meet the security requirements to separate the vehicle speed sensor drive gear. Place matchmarks on the ring gear then remove its 16 bolts before hitting the ring gear with a copper hammer to disassemble it. To disassemble the ring gear side use Special Service Tool: 09950-00020, 09950-00030, 09950-40011 (09957-04010), 09950-00010 (09951-00450) while setting the claw to the bearing inner race at the indented position. The dial indicator should be used to measure side gear backlash which must remain between 0.05 - 0.20 mm (0.0020 - 0.0079 inch); if the standard is not met install the appropriate thrust washer. The differential case disassembly process begins with removing the straight pin through pin punching and hammering then further includes removal of the pinion shaft and complete extraction of two pinions and side gears together with their respective four thrust washers. After removing the oil seal with a screwdriver and hammer, use a brass bar along with hammer to drive out the tapered roller bearing outer race. Then install a thinner shim followed by using Special Service Tool: 09316-60011 (09316-00011, 09316-00041) and a press to mount a new tapered roller bearing outer race. Install a new oil seal following the use of Service Tool: 09316-60010 (09316-00011, 09316-00031) until it reaches a depth of 3.5 ± 0.5 mm (0.138 ± 0.020 inch) while applying MP grease to the lip. To finish the assembly process on the transaxle case side technicians must drive out the oil seal after removing the tapered roller bearing outer race by using Special Service Tool: 09316-60011 (09316-00011, 09316-00021). Reinstalling the oil baffle correctly when its projection fits into the case side cutout. Before installing new components you must utilize Special Service Tools: 09950-60020 (09951-00890), 09950-70010 (09951-00150) together with a press while installing a new tapered roller bearing outer race. Next drive in a new oil seal using Special Service Tool: 09316-60011 (09316-00011, 09316-00041) to a depth of 0 - 0.5 mm (0 - 0.020 inch) and coat the oil seal lip with MP grease. Gear oil should be applied to all sliding and rotating components and then the correct thrust washers should be installed before inserting the pinion shaft to check side gear backlash. Insert the straight pin and apply the supplied calk material to the hole areas located around the differential case. Strengthen the ring gear by first cleaning the interface then submerging it in boiling water before rushing its installation onto the differential case and matching position pins. After the ring gear reaches room temperature users should install set bolts before uniform torquing them to 106 Nm (1,080 kgf-cm, 78 ft. lbs.). To install the ring gear side of the tapered roller bearing use Special Service Tool: 09316-60011 (09316-00011) for bearing press installation while replacing both tapered roller bearing and outer race. To install the new tapered roller bearing at the vehicle speed sensor drive gear side, place the component properly to prevent movement and apply Special Service Tool: 09316-20011, 09316-60011 (09316-00011), a steel plate, and press. To check differential tapered roller bearing preload measure the assembly torque with Special Service Tool: 09564-32011 while using a torque wrench until the readings fall within new and reused bearing specifications.