×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota RAV4 A/C Compressor

Air Conditioning Compressor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 A/C Compressors found

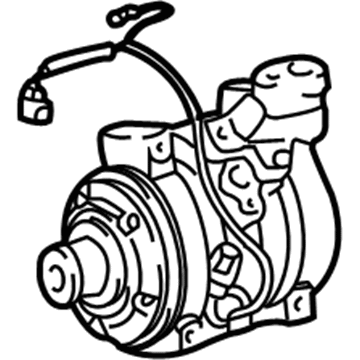

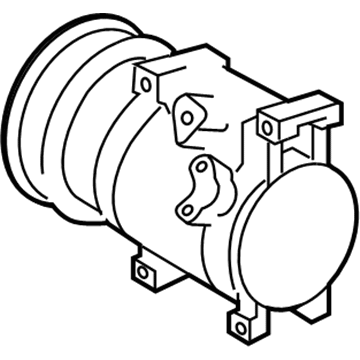

Toyota RAV4 Compressor Assembly

Part Number: 88320-42080-84$398.91 MSRP: $585.78You Save: $186.87 (32%)Ships in 1-3 Business Days

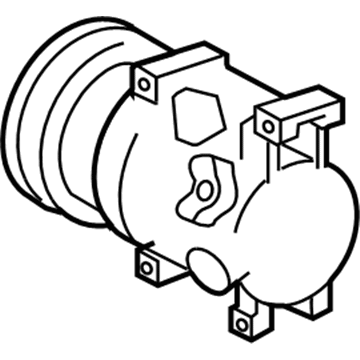

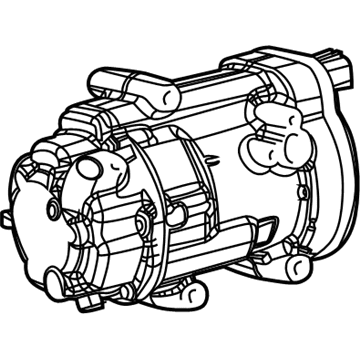

Toyota RAV4 Compressor Assembly

Part Number: 88310-42270$452.97 MSRP: $616.83You Save: $163.86 (27%)Ships in 1-2 Business Days

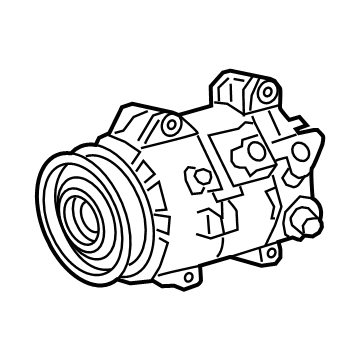

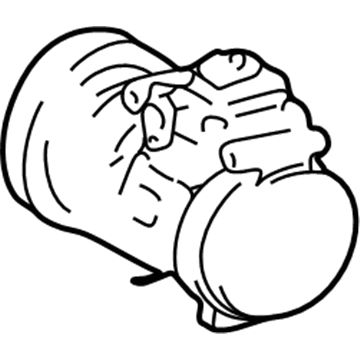

Toyota RAV4 Compressor

Part Number: 88310-33330$522.20 MSRP: $711.08You Save: $188.88 (27%)Ships in 1-3 Business Days

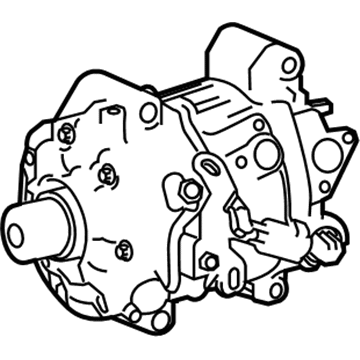

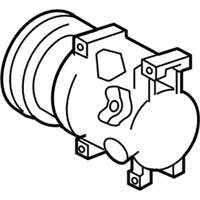

Toyota RAV4 Compressor

Part Number: 88310-0R040$516.64 MSRP: $760.68You Save: $244.04 (33%)Ships in 1-3 Business Days

Toyota RAV4 Compressor Assembly

Part Number: 88310-0R014$617.32 MSRP: $908.90You Save: $291.58 (33%)Ships in 1-3 Business DaysToyota RAV4 Compressor Assembly, With Pulley

Part Number: 88370-33031$1097.19 MSRP: $1611.15You Save: $513.96 (32%)Ships in 1-3 Business DaysToyota RAV4 Compressor Assembly

Part Number: 88320-42120-84$441.21 MSRP: $647.89You Save: $206.68 (32%)Ships in 1-3 Business DaysToyota RAV4 Compressor Assembly

Part Number: 88310-42180-84$411.28 MSRP: $603.94You Save: $192.66 (32%)Ships in 1-3 Business DaysToyota RAV4 Compressor Assembly

Part Number: 88310-42140-84$411.28 MSRP: $603.94You Save: $192.66 (32%)Ships in 1-3 Business DaysToyota RAV4 Compressor

Part Number: 88320-42140$666.35 MSRP: $860.64You Save: $194.29 (23%)Ships in 1-3 Business DaysToyota RAV4 Compressor

Part Number: 88320-42150$647.39 MSRP: $869.24You Save: $221.85 (26%)Ships in 1-3 Business DaysToyota RAV4 Compressor

Part Number: 88310-0R041$557.16 MSRP: $756.22You Save: $199.06 (27%)Ships in 1-3 Business DaysToyota RAV4 Compressor Assembly

Part Number: 88370-33051$1055.78 MSRP: $1515.35You Save: $459.57 (31%)Ships in 1-3 Business DaysToyota RAV4 Compressor

Part Number: 88310-42531$482.48 MSRP: $705.65You Save: $223.17 (32%)Ships in 1-3 Business DaysToyota RAV4 Compressor Assembly, W/Pulley

Part Number: 88310-06570$605.28 MSRP: $894.27You Save: $288.99 (33%)Ships in 1-3 Business Days

Toyota RAV4 A/C Compressor

Choose genuine A/C Compressor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Compressor for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 A/C Compressor Parts and Q&A

- Q: How to remove the A/C Compressor and pulley on Toyota RAV4?A:The first step to remove the 2AZ-FE engine air conditioning compressor and pulley demands a discharge of refrigerant substance from the refrigeration system. Before putting away the cable from the negative battery terminal maintain a minimum wait time of 90 seconds to stop Air Bag and seat belt pretensioner activation. Separate the No. 1 cooler refrigerant suction hose by unfastening its bolt and O-ring while minimizing foreign material ingress by covering exposed areas with vinyl tape. The procedure is repeated for removing the No. 1 cooler refrigerant discharge hose. Remove the engine under cover for No. 1 before taking out the V belt in sections from the fan and generator. You must disconnect the cooler compressor connector and separate the 4 bolts when there is no stud bolt but if there is you should detach the 3 bolts and nut to remove the cooler compressor.

- Q: How to install the A/C Compressor and pulley on Toyota RAV4?A:The air conditioning compressor and pulley installation requires adjusting the compressor oil through refrigerator gas service valve discharge and manual oil drainage from new components that totals 130 + 15 cc (4.6 + 0.51 fl.oz.) and includes remaining oil from previous components. The procedure of checking the compressor oil requires safe handling of coolers during removal and installation because both excessive or insufficient oil will affect the refrigerant's operation. The oil system requires ND-OIL 8 as its specific product or any approved substitute as compressor fluid. To install the cooler compressor assembly either without or with a stud bolt you should tighten four bolts to 24.5 Nm (250 kgf-cm, 18 ft-lbf) or use three bolts with a nut following the same torque setting. Installation of the No. 1 discharge hose starts by removing vinyl tape, applying compressor oil to both the fitting surface and new ring before installation with a bolt tightened to 9.8 Nm (100 kgf-cm, 7 ft-lbf). Repetition of this installation method should occur for the No. 1 cooler refrigerant suction hose. The procedure requires installation of the fan and generator V belt alongside the No. 1 engine under cover and connecting the cable to the negative battery terminal. The last step includes charging the refrigerant while allowing the engine to warm during an examination for leaking refrigerant.