×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

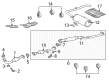

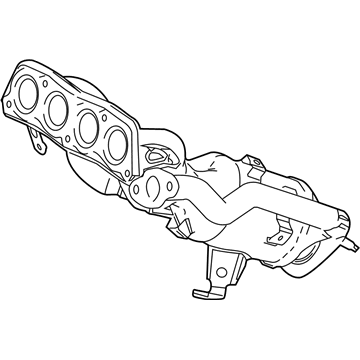

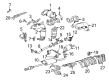

OEM Toyota Highlander Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Exhaust Manifolds found

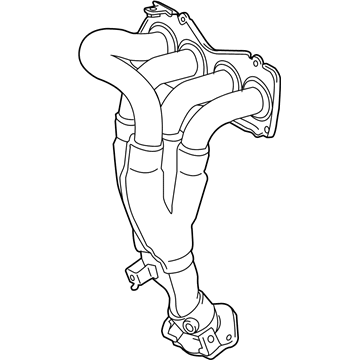

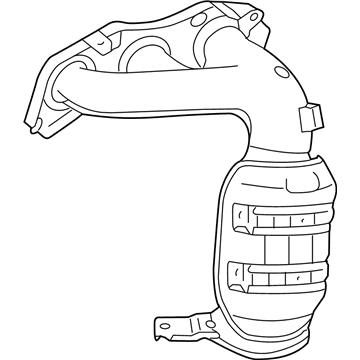

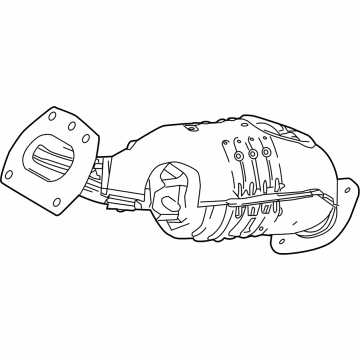

Toyota Highlander Exhaust Manifold, Passenger Side

Part Number: 17140-0P210$692.91 MSRP: $1015.46You Save: $322.55 (32%)Ships in 1-3 Business Days

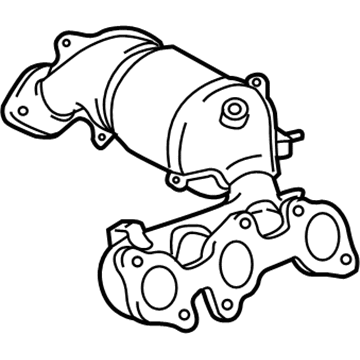

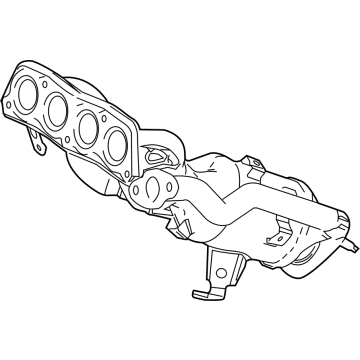

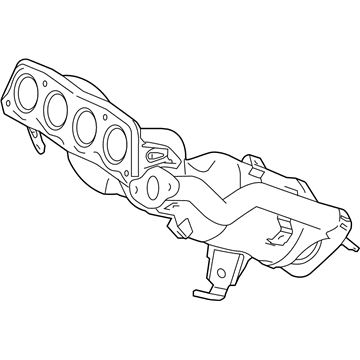

Toyota Highlander Exhaust Manifold

Part Number: 17141-36050$324.67 MSRP: $463.56You Save: $138.89 (30%)Ships in 1-3 Business Days

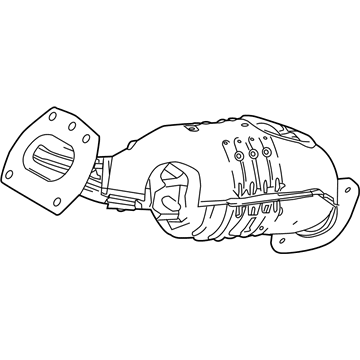

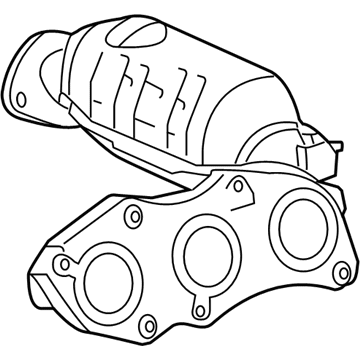

Toyota Highlander Exhaust Manifold, Passenger Side

Part Number: 17140-20120$541.72 MSRP: $793.91You Save: $252.19 (32%)Ships in 1-3 Business DaysToyota Highlander Manifold Assembly, Exhaust

Part Number: 17140-0P331$903.56 MSRP: $1324.18You Save: $420.62 (32%)Ships in 1 Business DayToyota Highlander Exhaust Manifold, Driver Side

Part Number: 17150-31380$1510.67 MSRP: $2213.90You Save: $703.23 (32%)Ships in 1-3 Business DaysToyota Highlander Exhaust Manifold, Passenger Side

Part Number: 17140-0P080$1182.09 MSRP: $1732.37You Save: $550.28 (32%)Ships in 1-3 Business DaysToyota Highlander Manifold, Exhaust, Passenger Side

Part Number: 17140-31390$942.72 MSRP: $1381.56You Save: $438.84 (32%)Ships in 1-3 Business DaysToyota Highlander Exhaust Manifold

Part Number: 17141-F0150$656.13 MSRP: $961.57You Save: $305.44 (32%)Ships in 1-3 Business DaysToyota Highlander Exhaust Manifold, Driver Side

Part Number: 17150-0P200$784.27 MSRP: $1149.36You Save: $365.09 (32%)Toyota Highlander Exhaust Manifold, Passenger Side

Part Number: 17140-31410$1510.67 MSRP: $2213.90You Save: $703.23 (32%)Ships in 1-3 Business DaysToyota Highlander Exhaust Manifold, Driver Side

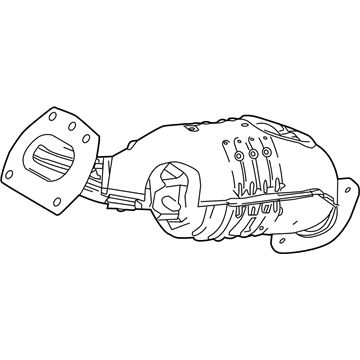

Part Number: 17150-0P430$584.29 MSRP: $856.27You Save: $271.98 (32%)Toyota Highlander Catalytic Converter, Driver Side

Part Number: 17150-0P331$903.56 MSRP: $1324.18You Save: $420.62 (32%)Toyota Highlander Exhaust Manifold, Passenger Side

Part Number: 17140-0P430$615.95 MSRP: $902.68You Save: $286.73 (32%)Toyota Highlander Manifold, Exhaust

Part Number: 17141-F0010$633.32 MSRP: $928.14You Save: $294.82 (32%)Ships in 1-2 Business DaysToyota Highlander Catalytic Converter, Passenger Side

Part Number: 17140-0P250$1006.51 MSRP: $1475.04You Save: $468.53 (32%)Toyota Highlander Catalytic Converter

Part Number: 17141-F0130$632.64 MSRP: $927.14You Save: $294.50 (32%)Ships in 1-2 Business DaysToyota Highlander Exhaust Manifold, Passenger Side

Part Number: 17140-0P350$732.18 MSRP: $1073.01You Save: $340.83 (32%)Ships in 1-3 Business DaysToyota Highlander Exhaust Manifold, Driver Side

Part Number: 17150-31270$1118.42 MSRP: $1639.05You Save: $520.63 (32%)Ships in 1-3 Business DaysToyota Highlander Catalytic Converter, Driver Side

Part Number: 17150-0P250$1000.26 MSRP: $1465.90You Save: $465.64 (32%)Toyota Highlander Manifold Sub-Assembly, Exhaust, Driver Side

Part Number: 17150-0P150$1184.47 MSRP: $1735.86You Save: $551.39 (32%)

| Page 1 of 2 |Next >

1-20 of 31 Results

Toyota Highlander Exhaust Manifold

Choose genuine Exhaust Manifold that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Exhaust Manifold for your Toyota Highlander? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Highlander parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Highlander Exhaust Manifold Parts and Q&A

- Q: How to install the exhaust manifold on Toyota Highlander?A:The Air Fuel Ratio Sensor needs installation first before proceeding with the exhaust manifold setup. You should install the No. 2 exhaust manifold heat insulator using a bolt tightened to 25 Nm (250 kgf-cm, 18 ft-lbf). Use a new gasket to cover the cylinder head before securing the exhaust manifold assembly with 5 nuts according to sequence and torque them to 35 Nm (357 kgf-cm, 26 ft-lbf). Proceed with installing the plate and bolt it to the manifold before tightening until it reaches 25 Nm torque (250 kgf-cm and 18 ft-lbf). Connect the No. 2 manifold stay using a bolt with nut combinations that must be torqued to 43 Nm. Attach the wire harness bracket with a single bolt torqued to 12 Nm. Finally set the manifold stay into place with a bolt and nut which should be torqued to 43 Nm (438 kgf-cm, 32 ft-lbf). Before installing the front Exhaust Pipe assembly verify the compression spring's free length using a vernier caliper because it needs to measure 41.5 mm (1.64 in.)+ immediately replace if the length is less than required. Using a plastic hammer together with a wooden block properly place a new gasket into the exhaust manifold assembly before checking for correct installation without reusing or damaging the component. Insert a second new gasket to the front exhaust pipe before securing it with 2 compression springs and 4 bolts that need torquing up to 48 Nm (489 kgf-cm, 35 ft-lbf) and 56 Nm (571 kgf-cm, 41 ft-lbf) respectively. Finally connect the clamp and connector. Lastly, attach the 3 clips before screwing the front floor cover LH with its 2 screws and 4 bolts. This process requires the under No. 1 engine cover to be installed afterward.

- Q: How to remove the exhaust manifold on Toyota Highlander?A:The process of removing the 2GR-FE engine exhaust manifold begins with removing the right-hand front wheel then continuing with V-bank cover sub-assembly removal. The first step involves separating the engine under cover assembly and then eliminating both No. 1 and No. 2 engine under covers. Start the repair procedure by draining the engine coolant before separating the hose for radiator connection No. 1. The radiator reserve tank assembly can be removed by disconnecting hose [A] and removing 2 bolts [B]. Proceed to eliminate the No. 2 oil level dipstick guide and the air fuel ratio sensor for Bank 2 Sensor 1. Uninstall the No. 2 exhaust manifold heat insulator through the removal of its 3 bolts. Start by separating the propeller with center bearing shaft assembly when operating on 4WD models followed by the tail Exhaust Pipe assembly, center exhaust pipe assembly, front No. 3 exhaust pipe sub-assembly and front exhaust pipe assembly. Restore access to the No. 2 manifold stay after deleting its bolt and nut then disconnect the exhaust manifold sub-assembly LH by extracting all 6 nuts and removing its gasket. Set aside the manifold stay after removing its bolt and nut and disconnect the Bank 1 Sensor 1 air fuel ratio sensor connector and detach its clamp. To finish the repair disconnect all 6 nuts which detach the exhaust manifold sub-assembly RH as well as its gasket.