×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Corolla Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Exhaust Manifolds found

Toyota Corolla Exhaust Manifold

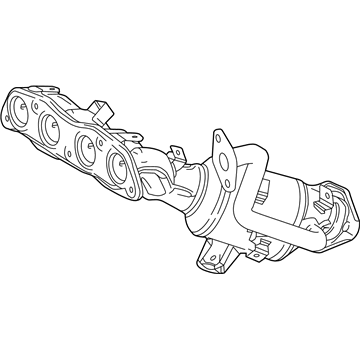

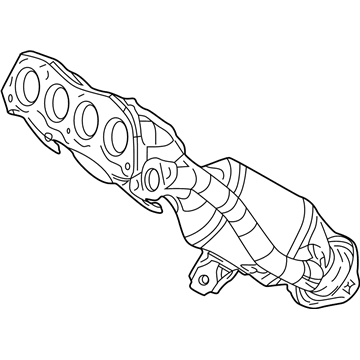

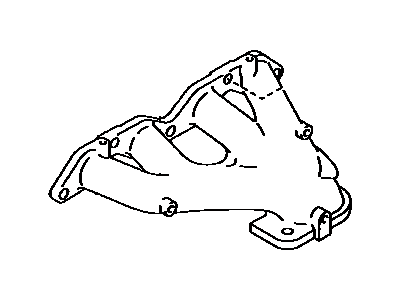

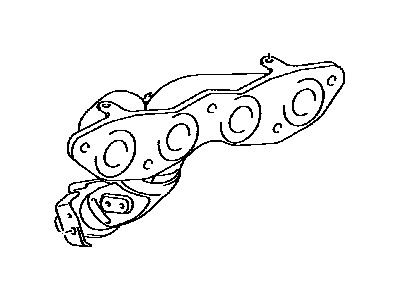

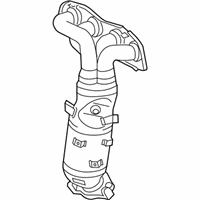

Part Number: 17141-37200$475.78 MSRP: $697.26You Save: $221.48 (32%)Ships in 1-3 Business DaysToyota Corolla Exhaust Manifold

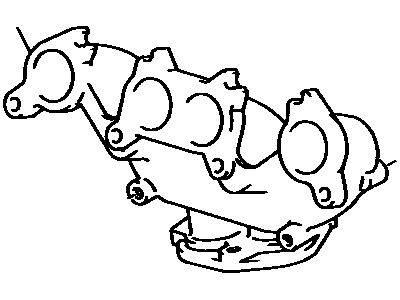

Part Number: 17141-24380$795.28 MSRP: $1165.50You Save: $370.22 (32%)Ships in 1-2 Business DaysToyota Corolla Exhaust Manifold

Part Number: 17141-37300$770.99 MSRP: $1129.91You Save: $358.92 (32%)Ships in 1-2 Business DaysToyota Corolla Exhaust Manifold

Part Number: 17141-37201$475.78 MSRP: $697.26You Save: $221.48 (32%)Ships in 1-3 Business DaysToyota Corolla Exhaust Manifold

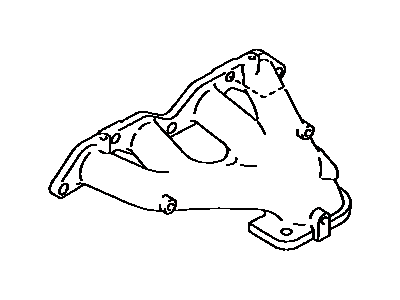

Part Number: 17141-24230$643.31 MSRP: $942.77You Save: $299.46 (32%)Ships in 1-3 Business DaysToyota Corolla Manifold, Exhaust

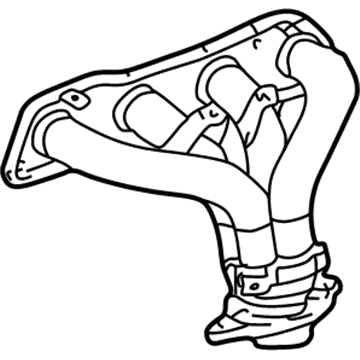

Part Number: 17141-F2010$665.78 MSRP: $975.71You Save: $309.93 (32%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 29 Results

Toyota Corolla Exhaust Manifold

Choose genuine Exhaust Manifold that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Exhaust Manifold for your Toyota Corolla? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Corolla parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Corolla Exhaust Manifold Parts and Q&A

- Q: How to remove the exhaust manifold on Toyota Corolla?A:The process to remove the 2ZR-FE exhaust manifold begins with front wiper arm head cap removal then subsequent removal of front wiper arm and blade assembly from both left and right sides. The next step requires removal of the hood to cowl top seal and both the center No. 1 cowl top ventilator louver and left cowl top ventilator louver. The windshield Wiper Motor and link assembly get detach first before removing the outer cowl top panel (TMC Made) or the outer cowl top panel (except TMC Made). Next in the process, remove both the No. 2 cylinder head cover alongside the air fuel ratio sensor part. Following the removal of the 4 bolts securing the No. 1 exhaust manifold heat insulator you should disconnect the heated oxygen sensor connector and extract the front Exhaust Pipe assembly with its 4 bolts and 4 compression springs far from the 2 exhaust pipe supports. After removing the 3 bolts securing the manifold stay the technician should remove the exhaust manifold after taking out 5 nuts and inspect the exhaust manifoldasket. To finish the process remove the No. 2 exhaust manifold heat insulator using 3 bolt removal.

- Q: How to install the exhaust manifold on Toyota Corolla?A:Begin installing the exhaust manifold for 2ZR-FE by placing the No. 2 exhaust manifold heat insulator on its position and fastening it using 3 bolts whose torque should be 12 Nm (122 kgf-cm, 9 ft-lbf). Fasten the exhaust manifold using 5 new nuts then torque them to 21 Nm (214 kgf-cm, 16 ft-lbf). The manifold stay gets installed using 3 bolts with a torques setting of 43 Nm (439 kgf-cm, 32 ft-lbf). Use a vernier caliper to measure the compression springs inside the front Exhaust Pipe assembly for their free length because their minimum specification might indicate replacement. Use new gaskets to build exhaust manifold-to-front exhaust pipe connections by applying a plastic hammer and wooden block to push them tightly in but only put them in the right direction and avoid all reuses and damages. Use the 4 exhaust pipe supports to fix the front exhaust pipe assembly before tightening the 4 bolts with 4 compression springs to 43 Nm (440 kgf-cm, 32 ft-lbf) and hook the heated oxygen sensor connector. The No. 1 exhaust manifold heat insulator requires installation with four bolts experiencing 12 Nm (122 kgf-cm, 9 ft-lbf) torque. The next installation procedure involves connecting the air fuel ratio sensor and No. 2 cylinder head cover and outer cowl top panel (both TMC Made and non-TMC Made models). As part of the installation connect the windshield Wiper Motor and link assembly, cowl top ventilator louvers, hood to cowl top seal and both front wiper arm and blade assemblies while inspecting for exhaust gas leaks during the procedure.