×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Celica Fuel Injector

Gas Injector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Fuel Injectors found

Toyota Celica Injector

Part Number: 23209-74100$182.43 MSRP: $260.47You Save: $78.04 (30%)Ships in 1-3 Business Days

Toyota Celica Injector

Part Number: 23209-74140$182.43 MSRP: $260.47You Save: $78.04 (30%)Ships in 1-3 Business Days

Toyota Celica Injector

Part Number: 23209-22060-01$182.43 MSRP: $260.47You Save: $78.04 (30%)Ships in 1-3 Business DaysToyota Celica Injector

Part Number: 23209-0D040$175.32 MSRP: $250.32You Save: $75.00 (30%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

Toyota Celica Fuel Injector

Choose genuine Fuel Injector that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Fuel Injector for your Toyota Celica? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Celica parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Celica Fuel Injector Parts and Q&A

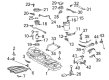

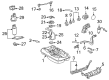

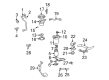

- Q: How to service and repair the fuel injector on Toyota Celica?A:Start the service procedure on the fuel injector by first removing the No. 2 cylinder head cover and the PCV hose that belongs to the 1ZZ-FE engine. First detach the fuel tube connector from its fuel pipe position before removing the fuel pipe clamp under consideration of pressurized fuel conditions. Begin by disconnecting the delivery pipe and four injectors through removal of their four connector connections followed by taking out three bolts before removing the delivery pipe together with the four injectors and fuel pipe. Remove both spacers from the cylinder head and extract the four injectors from the delivery pipe through the following procedure while discarding their O-ring and grommet components from each injector. The installation process includes the placement of grommets on all injectors followed by oiling new O-rings lightly with spindle oil or gasoline before insertion and application of oil to delivery pipe contact points with O-rings. After turning the delivery pipes insert the four injectors keeping their connectors facing outward then place the two spacers on the cylinder head. Lightly coat spindle oil or gasoline on the cylinder head and injector ring contact points and then place the delivery pipe with attached fuel pipe on the cylinder head above the injectors. Install the delivery pipe set of bolts and the fuel pipe bolt to check free injector movement. Replace any O-rings that do not allow smooth rotation. Tighten the delivery pipe bolts to the cylinder head with 19 N.m (190 kgf.cm, 14 ft.lbf) on 1ZZ-FE engines and 29 N.m (290 kgf.cm, 21 ft.lbf) on 2ZZ-GE engines before securing the fuel pipe bolt to 9 N.m (92 kgf.cm, 7 ft.lbf). The final steps involve connecting the fuel tube through its attachment to the fuel pipe followed by installation of the fuel pipe clamp while also putting back the No. 2 cylinder head cover component. The procedure for separating the fuel delivery pipe involves removing the fuel pipe clamp followed by pulling out the metallic connector of the fuel tube assembly and using Special Service Tool: 09268-21010. Clean the fuel tube connector area before disconnect and use hand power to disconnect the tubing while avoiding tools when needed to remove the retainer followed by a seal surface inspection for dirt before covering all disconnected parts against contamination.