×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2009 Toyota RAV4 Air Bag

Air Bag Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Air Bags found

2009 Toyota RAV4 Passenger Air Bag, Upper

Part Number: 73960-0R012$634.34 MSRP: $929.63You Save: $295.29 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Air Bag Assembly, Instrument Panel; Instrument Panel Air Bag, Upper; Passenger Inflator Module; Air Bag Assembly, Instrument Panel Passenger W/O Door

- Position: Upper

- Replaces: 73960-0R010

- Part Name Code: 73960A

- Item Weight: 8.60 Pounds

- Item Dimensions: 14.9 x 11.7 x 8.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 73960-0R012

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

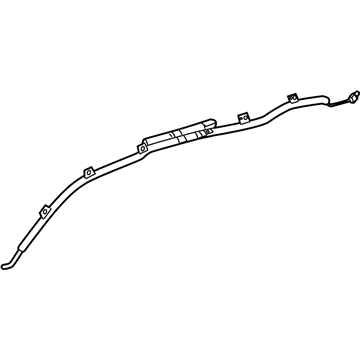

2009 Toyota RAV4 Inflator Curtain, Driver Side

Part Number: 62180-0R010$721.87 MSRP: $1057.90You Save: $336.03 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Air Bag Assembly, Curtain Shield; Curtain Air Bag, Left; Head Air Bag; Air Bag Assembly, Curtain Shield, Driver Side

- Position: Driver Side

- Replaces: 62180-42040

- Part Name Code: 62180A

- Item Weight: 12.20 Pounds

- Item Dimensions: 47.4 x 18.9 x 9.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 62180-0R010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota RAV4 Inflator Curtain, Passenger Side

Part Number: 62170-0R010$721.87 MSRP: $1057.90You Save: $336.03 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Air Bag Assembly, Curtain Shield; Curtain Air Bag, Right; Head Air Bag; Air Bag Assembly, Curtain Shield, Passenger Side

- Position: Passenger Side

- Replaces: 62170-42050

- Part Name Code: 62170A

- Item Weight: 11.70 Pounds

- Item Dimensions: 46.4 x 18.4 x 9.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 62170-0R010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota RAV4 Front Seat Air Bag, Driver Side

Part Number: 73920-42031$429.47 MSRP: $629.40You Save: $199.93 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Air Bag Assembly, Front Seat; Seat Air Bag, Front Left; Air Bag Assembly, Front Seat, Driver Side

- Position: Driver Side

- Replaces: 73920-42030

- Part Name Code: 73920A

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 73920-42031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota RAV4 Front Seat Air Bag, Passenger Side

Part Number: 73910-42031$391.42 MSRP: $573.62You Save: $182.20 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Air Bag Assembly, Front Seat; Seat Air Bag, Front Right; Air Bag Assembly, Front Seat, Passenger Side

- Position: Passenger Side

- Replaces: 73910-42030

- Part Name Code: 73910A

- Item Weight: 2.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 73910-42031

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2009 Toyota RAV4 Air Bag

Looking for affordable OEM 2009 Toyota RAV4 Air Bag? Explore our comprehensive catalogue of genuine 2009 Toyota RAV4 Air Bag. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2009 Toyota RAV4 Air Bag Parts Q&A

- Q: What are the essential procedures to follow for safely handling Air Bag systems on 2009 Toyota RAV4?A: The vehicle includes a Supplemental Restraint System (SRS) containing sensors along with Air Bags and repair procedures should be followed exactly for avoiding unexpected Air Bag activation that leads to severe injuries. Waiting for 90 seconds after both engine ignition shut-off and negative terminal battery removal is necessary to ensure SRS Back Up power depletes. Before negative battery terminal removal one must verify DTC conditions and all SRS components need protection from flames and hot air conditions. A detailed inspection should be conducted on SRS components immediately after collisions that result from minor impacts and removal of Air Bag sensors can be performed if they risk breakdown during future repairs. New SRS parts should be used throughout replacement processes while SRS components must be left intact without any attempt to repair them and all dropped or damaged parts need replacement. The electrical testing requires an ohmmeter/voltmeter with minimum impedance of 10 kOhms/V together with strict adherence to the information labels warning instructions attached to SRS parts. Whenever completing work on SRS components the SRS warning light check must be executed. Note down the essential memory settings for every system before unpowering the negative battery termial and restore them when work concludes. Use Air Bag sensors only after the negative terminal wait time of 90 seconds expires while installing these components properly without deploying sensors that fall to the ground. DTCs must be verified when an Air Bag fails to deploy and new sensors are essential for Air Bags that activate during deployment. Yellow color coding of SRS connectors helps identification while their connection mechanisms secure and prevent unintended disconnect. Strict procedures exist for disconnecting and reconnecting the steering pad connector and those of the front passenger Air Bag assembly and curtain shield Air Bag assembly and front seat side Air Bag assembly and center Air Bag sensor assembly with proper locking mechanism engagement and secure connections.