×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Sienna Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Water Pump found

2006 Toyota Sienna Water Pump

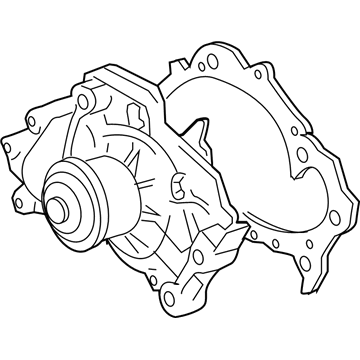

Part Number: 16100-29085$75.09 MSRP: $105.41You Save: $30.32 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Water; Engine Water Pump; Water Pump Assembly; Pump Assembly, Engine Water

- Replaces: 16100-09070

- Part Name Code: 16100

- Item Weight: 2.50 Pounds

- Item Dimensions: 10.0 x 6.5 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 16100-29085

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Sienna Water Pump

Looking for affordable OEM 2006 Toyota Sienna Water Pump? Explore our comprehensive catalogue of genuine 2006 Toyota Sienna Water Pump. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Sienna Water Pump Parts Q&A

- Q: How to service and repair the water pump on 2006 Toyota Sienna?A: To service and repair the water pump, begin by draining the coolant and removing the front wheel RH, front wiper arm head cap, front wiper arms RH and LH, cowl top ventilator louver sub-assembly, wiper link assembly, No. 1 cowl top cowl brace inner, cowl top panel sub-assembly outer front, front fender apron seal RH, No. 1 V (cooler compressor to crankshaft pulley) belt, vane pump V belt, engine moving control rod, engine mounting stay No. 2 RH, No. 2 generator bracket, crankshaft pulley, timing belt No. 1 cover, timing belt No. 2 cover, engine mounting bracket RH, No. 2 timing belt guide, timing belt, No. 2 timing belt idler sub-assembly, camshaft timing pulley, timing belt No. 3 cover, and No. 1 timing belt idler sub-assembly by using a 10 mm socket hexagon wrench to remove the pivot bolt, timing belt idler No. 1, and plate washer. The water pump assembly requires removal by unfastening three bolts and nuts and withdrawing the water pump itself. Begin installation by adding a new gasket to the water pump before adding the 3 bolts and 3 nuts with 8.0 Nm (82 kgf-cm, 71 inch lbs.) torque. After that, use a 10 mm socket hexagon wrench to fit the plate washer along with timing belt idler No. 1 using its pivot bolt and torque to 34 Nm (347 kgf-cm, 25 ft. lbs.). The sequence continues with timing belt No. 3 cover installation followed by camshaft timing pulley installation then the No. 2 timing belt idler sub-assembly before timing belt inspection and finishing with the timing belt installation alongside No. 1 chain tensioner assembly, No. 2 timing belt guide, engine mounting bracket No. 2 RH, timing belt No. 2 cover, timing belt No. 1 cover, crankshaft pulley, No. 2 generator bracket, engine mounting stay No. 2 RH, engine moving control rod, vane pump V belt, and No. 1 V (cooler The cowl top panel sub-assembly outer front should be installed with the No. 1 cowl top to cowl brace inner and wiper link assembly and both front wiper arms LH and RH followed by the installation of the front wheel RH. The process ends with adding coolant followed by engine coolant leakage inspection.