×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

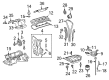

OEM 2006 Scion xA Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Timing Chain found

2006 Scion xA Timing Chain

Part Number: 13506-21050$209.11 MSRP: $298.55You Save: $89.44 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly, Timing; Chain Sub-Assembly

- Part Name Code: 13506

- Item Weight: 1.20 Pounds

- Item Dimensions: 6.3 x 3.3 x 1.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13506-21050

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Scion xA Timing Chain

Looking for affordable OEM 2006 Scion xA Timing Chain? Explore our comprehensive catalogue of genuine 2006 Scion xA Timing Chain. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Scion xA Timing Chain Parts Q&A

- Q: How to service the timing chain on 2006 Scion xA?A: Service operations must begin by disconnecting the negative battery cable and waiting for 90 seconds or more to stop Air Bag activation. The service requires removing the front right wheel along with four nuts from the cylinder head cover then separating the 4 bolts on the ignition coils before detaching ventilation hoses from the cylinder head cover. The maintenance sequence begins with nine bolt removal and two nut removal from the cylinder head cover after which follows the generator V belt and generator and engine under cover RH and engine oil drainage along with coolant. The vane pump V belt must be removed together with the water pump pulley and water pump and crankshaft pulley through precise timing mark alignment and use of Special Service Tool: 09213-58012 (91111-50845), 09330-00021 to extract the pulley bolt. The puller 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021) available as Special Service Tool will help remove pulleys when necessary. The procedure starts with disconnecting the oil control valve connector and removing the camshaft timing oil control valve assembly together with the crankshaft position sensor, engine mounting bracket insulator RH and engine mounting bracket RH. A sequence of components for removal includes the timing chain cover, oil pump seal, No. 1 chain tensioner, chain tensioner slipper, No. 1 chain vibration damper and the chain itself. The No. 1 cylinder should be positioned to 20 degrees ATDC during installation. The installation requires a chain vibration damper bolted with specified torque (9.0 Nm) before aligning timing marks and finally applying torque (9.0 Nm) to chain tensioner slipper and tensioner followed by exhaust and intake camshaft timing sprocket tension check. The installation includes fitting the oil pump seal followed by the timing chain cover and water pump then engine mounting bracket RH (torque: 55 Nm) and finally engine mounting insulator RH (torque: 45 Nm for bolt A, 52 Nm for bolt B and nut). Connect the camshaft timing oil control valve assembly along with a new O-ring (torque: 7.5 Nm) and position the crankshaft sensor immediately afterwards. Install the water pump pulley and crankshaft pulley (torque: 128 Nm using Special Service Tool: 09330-00021, 09213-58012 (91111-50845)). The cylinder head cover needs seal packing before installation using 9 bolts together with 2 seal washers and 2 nuts (torque: 10 Nm) and ventilation hoses to be connected along with ignition coils (torque: 9.0 Nm). The last step involves installing the No. 2 cylinder head cover with a torque of 7.0 Nm while also adding the generator, vane pump V belt, generator V belt for adjustment followed by drive belt tension inspection of the oil pan drain plug installation (torque 37.5 Nm) and engine oil and coolant addition to check for leaks before battery terminal reconnection and necessary system initialization procedures post reconnect.