×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2005 Toyota Tacoma Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshaft Position Sensors found

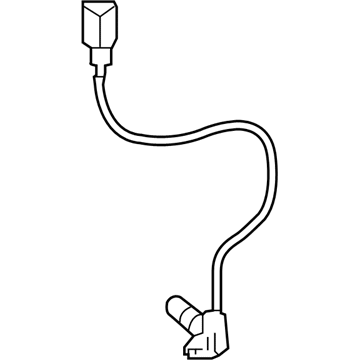

2005 Toyota Tacoma Camshaft Position Sensor, Driver Side

Part Number: 90919-T5005$102.96 MSRP: $144.53You Save: $41.57 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Engine Camshaft Position Sensor, Left; Crankshaft Position Sensor; Camshaft Sensor; Cam Sensor; Sensor, Cam Position; Engine Camshaft Position Sensor

- Manufacturer Note: (L)

- Position: Driver Side

- Replaces: 9004A-19003, 90919-05060, 90919-T5002

- Part Name Code: 11101E

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 3

- SKU: 90919-T5005

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

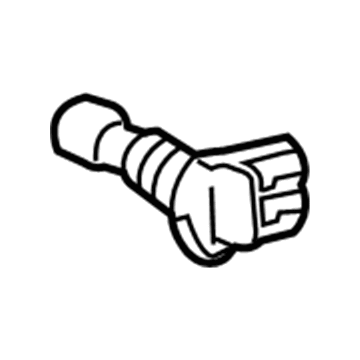

2005 Toyota Tacoma Crankshaft Position Sensor

Part Number: 90919-05059$133.23 MSRP: $188.60You Save: $55.37 (30%)Ships in 1 Business DayProduct Specifications- Other Name: Sensor, Crank Position; Engine Crankshaft Position Sensor; Crankshaft Sensor

- Part Name Code: 11301K

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.7 x 2.8 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 90919-05059

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

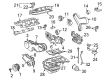

2005 Toyota Tacoma Sensor, Crank Position

Part Number: 90919-A5003$72.15 MSRP: $101.28You Save: $29.13 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Engine Crankshaft Position Sensor; Crankshaft Position Sensor

- Manufacturer Note: (L)

- Replaces: 90919-05057

- Part Name Code: 11401G

- Item Weight: 0.40 Pounds

- Item Dimensions: 4.9 x 2.8 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 90919-A5003

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota Tacoma Crankshaft Position Sensor

Looking for affordable OEM 2005 Toyota Tacoma Crankshaft Position Sensor? Explore our comprehensive catalogue of genuine 2005 Toyota Tacoma Crankshaft Position Sensor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2005 Toyota Tacoma Crankshaft Position Sensor Parts Q&A

- Q: How to replace the Crankshaft Position Sensor on 2005 Toyota Tacoma?A: The first step to replace the Crankshaft Position Sensor requires disconnecting the negative battery cable. The first step includes removal of the pre-runner or 4WD type engine under cover sub-assembly No.1 followed by fan and generator belt with air conditioning. The first step requires removing the compressor and magnetic clutch and idle pulley assembly with bracket by breaking the 5 bolts loose. Unplug the crankshaft position sensor connector before disconnecting its wire harness clamps then pushing out the bolt to remove the crankshaft position sensor. The crankshaft position sensor installation requires using engine oil to lubricate its O-ring then installing the sensor with the bolt before torquing it to 8.5 N.m (87 kgf.cm, 75 in.lbf) but making sure the O-ring stays free of creases and clamps. Connect the crankshaft position sensor connector along with both wire harness clamps. Install the idle pulley assembly with bracket by uniformly tightening the 5 bolts according to the specified sequence and torquing bolt A to 21 N.m (214 kgf.cm, 16 ft.lbf) and bolts B and C to 43 N.m (438 kgf.cm, 32 ft.lbf). The next procedure requires installation of compressor units and magnetic clutch followed by fan assembly and generator belt then engine under cover subassembly No.1. Finish by connecting the cable to the negative battery terminal and tighten it for 3.9 N.m (40 kgf.cm, 35 in.lbf).