×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2004 Toyota Matrix Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Alternators found

2004 Toyota Matrix Alternator

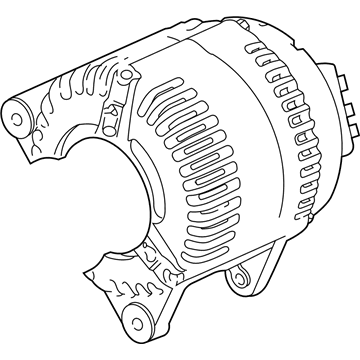

Part Number: 27060-0D110-84$195.42 MSRP: $237.30You Save: $41.88 (18%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Reman Alternator 1Zz

- Replaces: 27060-0D110

- Item Weight: 12.80 Pounds

- Item Dimensions: 9.3 x 7.2 x 8.2 inches

- Condition: New

- SKU: 27060-0D110-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Matrix Alternator

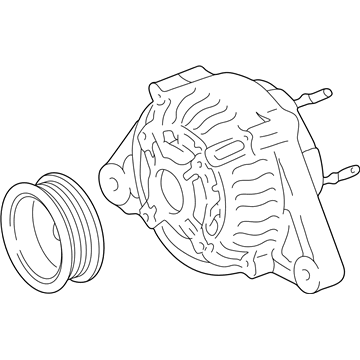

Part Number: 27060-22090-84$197.02 MSRP: $279.59You Save: $82.57 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Reman Alternator W/R

- Item Weight: 16.10 Pounds

- Item Dimensions: 13.2 x 10.7 x 8.8 inches

- Condition: New

- SKU: 27060-22090-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Matrix Alternator

Looking for affordable OEM 2004 Toyota Matrix Alternator? Explore our comprehensive catalogue of genuine 2004 Toyota Matrix Alternator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2004 Toyota Matrix Alternator Parts Q&A

- Q: How to service and repair the alternator on 2004 Toyota Matrix?A: Start alternator service and repair by using Special Service Tool 09820-63010 (09820-06010, 09820-06020) to detach the pulley. First tighten the pulley holding tool with a torque wrench until the socket reaches 39 N.m (398 kgf.cm, 29 ft.lbf) while it secures to the rotor shaft. Secure the adapter inside a vise frame before installing the socket which leads to the pulley attachment. Finally, add the pulley nut to the assembly. After turning the pulley holding tool counterclockwise while keeping an eye on the rotor shaft safety, replace the pulley holding tool into the adapter to remove the alternator followed by detaching the socket and pulley holding tool before removing the pulley nut and pulley. To detach the generator brush holder assembly begin by removing the nut followed by the terminal insulator and the screw and nut from the terminal plate before removing the two rear end cover nuts then the generator brush cover and its two screws and finally the removal of the generator plate seal from the generator rectifier end frame. Unscrew the three regulator assembly screws to access the generator holder with rectifier which can be removed by disconnecting four screws. Special Service Tool 09286-46011 needs to be used to remove the generator rectifier end frame after removing its terminal insulators and generator cord clip and four bolts. The procedure starts by removing the drive end frame rotor through removal of its generator washer then rotor. Verify that the generator brush holder exhibit brush length measurements in a range of 9.5 to 11.5 mm (0.374 to 0.453 in.) by using vernier calipers and execute a replacement if brush length falls below 1.5 mm (0.059 in.). A continuity test between F and B and between F and E terminals of the generator regulator assembly using an ohmmeter requires a replacement of the regulator if these measurements do not match specifications. The generator holder with rectifier should be examined for continuity at each terminal where necessary and replacement must be performed. The generator rotor assembly requires checks for smoothness and wear together with an inspection of the bearing condition and slip rings' resistance levels where resistance outside 2.1 to 2.5 ohms will require rotor replacement at 20 degrees Celsius (68 degrees Fahrenheit). The slip ring must undergo a continuity test both with the rotor core and its diameter should be checked. Replacing the rotor becomes necessary if it measures less than 12.8 mm (0.504 in.). The generator rectifier end frame should be inspected for signs of roughness or wear while checking continuity between coil leads as well as between coil lead and body and performing a replacement if the continuity reading is not within specifications. The removal of generator rotor bearing on the 1ZZ-FE engine requires clamping the rotor in a vise followed by using Special Service Tool 09820-00021 to eliminate both the bearing cover and bearing components while being cautious to prevent fan damage. To install the new bearing position the rotor on the pulley then secure the inside bearing cover before using Special Service Tool 09820-00031 to drive in the bearing while you will insert the outside bearing cover using Special Service Tool 09285-76010. The generator drive end frame bearing requires removal of its retainer plate before pressing out the bearing with Special Service Tool 09950-60010 (09951-00350) or 09950-70010 (09951-07100). Install new bearings and set the retainer plate with 3.0 N-m torques (31 kgf-cm or 27 in.-lbf). Follow the reassembly process by attaching the generator drive end frame to the pulley before placing the generator rotor and generator washer. To assemble the generator rectifier end frame first use a press along with a socket wrench to seal it in place before using the generator cord clip and applying four nuts according to specified torque requirements then install the terminal insulators. Use four screws to connect the generator holder with rectifier according to the torque specification of 2.9 N-m (30 kgf-cm, 26 in.-lbf) first. Proceed with attaching the generator regulator assembly by using three screws at 2.0 N-m (20 kgf-cm, 18 in.-lbf) followed by the generator brush holder assembly requiring two screws at 2.0 N-m (20 kgf-cm, 18 in.-lbf) and correct installation direction. Installation of the generator rear end cover requires two nuts torqued to 4.4 N-m (45 kgf-cm, 39 in.-lbf) along with the terminal plate torquing according to specified values and the terminal insulator nut torqued to 4.1 N-m (42 kgf-cm, 36 in.-lbf). Install and secure the pulley with Special Service Tool 09820-63010 (09820-06010, 09820-06020) by first hand-tightening the pulley nut followed by torqueing it to 39 N.m (398 kgf.cm, 29 ft.lbf) while using the pulley holding tool then torquing the pulley nut to 111 N.m (1,132 kgf.cm, 82 ft.lbf) without any smoothness limitations.