×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2004 Toyota Avalon Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Timing Belt found

2004 Toyota Avalon Timing Belt

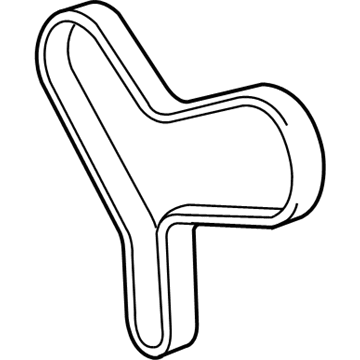

Part Number: 13568-09080$60.54 MSRP: $84.98You Save: $24.44 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Timing; Engine Timing Belt; Timing Belt Kit

- Replaces: 13568-09050

- Part Name Code: 13568

- Item Weight: 1.00 Pounds

- Item Dimensions: 14.0 x 12.1 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13568-09080

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Avalon Timing Belt

Looking for affordable OEM 2004 Toyota Avalon Timing Belt? Explore our comprehensive catalogue of genuine 2004 Toyota Avalon Timing Belt. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2004 Toyota Avalon Timing Belt Parts Q&A

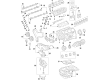

- Q: How to service and repair the timing belt on 2004 Toyota Avalon?A: The timing belt repair and servicing process requires technicians to start with the removal of RH front wheel along with RH fender apron seal and generator drive belt and PS pump drive belt after unbolted with 2 bolts. First disconnect the engine coolant reservoir hose from the water outlet. Then you should remove the ground strap connectors and engine moving control rod alongside the No.2 RH engine mounting bracket. After that disconnect the No.2 generator bracket by loosening its pivot bolt and removing the nut and bracket. Next employ special service tools 09213-54015 (91651-60855), 09330-00021 to access the crankshaft pulley bolt and the tools described in the tool number 09950-50013 (09951-05010, 09952-05010, 09953-05010, 09953-05020, 09954-05021) to dismount the pulley. First, remove the No.1 timing belt cover through 4 bolt removal and then proceed to the timing belt guide before moving on to the No.2 timing belt cover by disconnecting engine wire protector clamps and taking out 5 bolts. The RH engine mounting bracket installation requires removing two bolts and one nut before setting the No.1 cylinder to TDC/compression by temporarily installation of the crankshaft pulley bolt while aligning the timing marks where the crankshaft must turn clockwise. You must inspect the timing belt for its 3 installation marks and front mark before you remove it; create new marks if some are absent. Start by loosening two timing belt tensioner bolts in alternate directions before removing the timing belt and proceeding to remove camshaft timing pulleys using special service tool 09249-63010 together with special service tools 09960-10010 (09962-01000, 09963-01000) for the right-hand and left-hand timing pulleys. The technician should remove the No.2 idler pulley and the No.1 idler pulley using a 10 mm hexagon wrench followed by the crankshaft timing pulley removal after unbolted the timing belt plate and utilizing special service tool: 09950-50012 (09951-05010, 09952-05010, 09953-05010, 09953-05020, 09954-05011). Caution must be taken to avoid touching the sensor part during this process. You should inspect each timing belt for defects while ensuring complete absence of bending and twisting as well as clear barriers to oil, water and steam. Additionally check all idler pulleys and timing belt tensioner for smooth operation and oil leakage. The installation process begins with the crankshaft timing pulley that needs alignment with the pulley set key before tightening the timing belt plate to 8 Nm (80 kgf-cm, 69 inch lbs.). Fix the No.1 idler pulley with adhesive three bond 1344 or loctite 242 while using part no. 08833-00080. Follow by installing the No.2 idler pulley which should move without resistance. People must install the RH camshaft timing pulley while aligning its knock pin and using special service tools: 09249-63010, 09960-10010 (09962-01000, 09963-01000) to apply 88 Nm (900 kgf-cm, 65 ft. lbs.) torque on the pulley bolt. Then they should repeat this process for the LH camshaft timing pulley with a torque of 125 Nm (1,300 kgf-cm, 94 ft. lbs.). The installation process includes setting the timing marks at TDC/compression of cylinder No.1 while installing the timing belt and following the specified sequence on a cold and contaminant-free engine. The timing belt tensioner installation requires inserting the push rod until it reaches the stopper position and tightening the 1.27 mm hexagon wrench followed by tensioner installation and crankshaft rotation to double-check valve timing. The last steps include installing the RH engine mounting bracket followed by No.2 timing belt cover then timing belt guide, after which install No.1 timing belt cover and crankshaft pulley using 215 Nm of torque (2,200 kgf-cm, 159 ft. lbs.). The next sequence of installation involves attaching the No.2 generator bracket, No.2 RH engine mounting bracket, engine moving control rod, reconnecting ground strap connectors, installing the engine coolant reservoir hose, PS pump and generator drive belts, followed by RH fender apron seal and RH front wheel installation. A final check through a road test examines noise, shock, slippage, shift points and smooth operation.