×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Land Cruiser Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Alternator found

2003 Toyota Land Cruiser Alternator

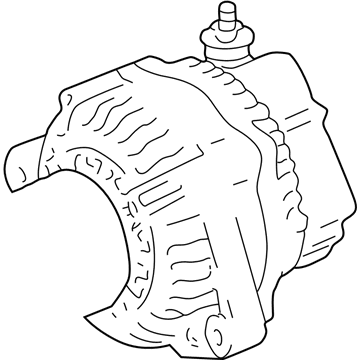

Part Number: 27060-50360-84$227.25 MSRP: $302.67You Save: $75.42 (25%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Alternator Assembly, With Regulator

- Replaces: 27060-50330-84, 27060-50330, 27060-50360

- Item Weight: 15.80 Pounds

- Item Dimensions: 11.3 x 9.5 x 7.3 inches

- Condition: New

- SKU: 27060-50360-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Land Cruiser Alternator

Looking for affordable OEM 2003 Toyota Land Cruiser Alternator? Explore our comprehensive catalogue of genuine 2003 Toyota Land Cruiser Alternator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Land Cruiser Alternator Parts Q&A

- Q: How to service and repair the alternator on 2003 Toyota Land Cruiser?A: Service and repair of the alternator requires drained engine coolant followed by generator drive belt removal through tensioner loosening using the left-hand thread pulley bolt. Service professionals should begin repairs by taking out engine under cover No.1 and radiator assembly together with the PS vane pump pulley before generator disconnection. The service requires disconnecting the generator connector followed by removing the rubber cap and nut which disconnects the generator wire after detaching the generator wire clamp from the cord clip. Take out the generator after you disconnect its bolt along with its two nuts. Place the generator correctly by fitting it with the bolt and two nuts then twist them to 39 N.m (400 kgf.cm, 29 ft.lbf) for the 10 mm nut and 15.5 N.m (158 kgf.cm, 11 ft.lbf) for the 8 mm nut. Secure the generator wire to the generator connector using the nut while torquing it to 9.8 N.m (100 kgf.cm, 87 in.lbf) and then apply the generator wire clamp and terminal cap to the cord clip. Now focus on putting in the PS vane pump pulley along with the radiator components and generator drive belt while using a counter-clockwise motion on the belt tensioner. The technician begins by filling the engine coolant before checking for any leaks. Engine coolant level is reconfirmed and an on-vehicle inspection takes place before engine under cover No.1 installation.