×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Highlander Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Timing Chains found

2003 Toyota Highlander Timing Chain

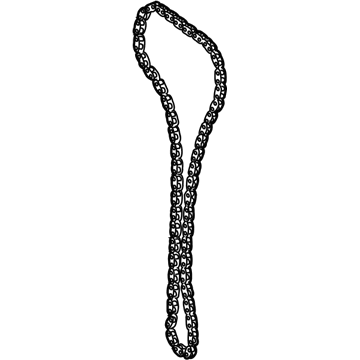

Part Number: 13506-0H011$268.87 MSRP: $383.89You Save: $115.02 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly, Timing; Engine Timing Chain; Chain Sub-Assembly

- Replaces: 13506-28020, 13506-0H031, 13506-28010, 13506-28011, 13506-28021, 13506-0H010

- Part Name Code: 13506

- Item Weight: 1.20 Pounds

- Item Dimensions: 6.8 x 3.4 x 1.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13506-0H011

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Timing Chain

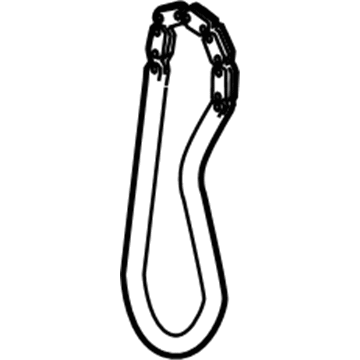

Part Number: 13507-28010$89.46 MSRP: $125.57You Save: $36.11 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain Sub-Assembly, Oil; Engine Timing Chain; Chain; Chain Sub-Assembly

- Replaces: 13507-0H020

- Part Name Code: 13507

- Item Weight: 0.70 Pounds

- Item Dimensions: 2.6 x 2.4 x 0.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13507-28010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Timing Chain

Looking for affordable OEM 2003 Toyota Highlander Timing Chain? Explore our comprehensive catalogue of genuine 2003 Toyota Highlander Timing Chain. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Highlander Timing Chain Parts Q&A

- Q: How to replace the timing chain on 2003 Toyota Highlander?A: Replacement of the timing chain starts by taking away the hood sub-assembly, front right wheel, engine under cover No.1, front fender splash shield front right, and front fender apron seal right. After draining all engine oil you must install the new gasket along with drain plug then tighten it to 25 Nm (250 kgf-cm, 18 ft. lbs.). The removal sequence starts with extracting engine mounting stay No.2 right followed by removing the exhaust pipe assembly front along with the engine mounting bracket No.2 right and engine moving control rod with bracket after unscrewing 3 bolts and engine mounting stay No.2 right. Detach the generator assembly then remove the fan and generator V belt before separating the vane pump assembly without disturbing the hose connection. The technician will disconnect engine cover sub-assembly No.1 along with ignition coil assembly and ventilation hoses. Begin by removing the bolt from the cylinder head cover sub-assembly before disconnecting the engine wire harness clamp and afterward removing 8 bolts along with 2 nuts. The technician follows Procedure to set the first cylinder at TDC compression stage then applies the pulley loose bolt tool: 09213-54015 (91651-60855) and 09330-00021 and removes it using tool set 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021). You must use Special Service Tool: 09032-00100 with its corresponding sealer cutting tool to remove the crankshaft position sensor and oil pan sub-assembly. Twelve bolts and two nuts need to be taken out for this procedure. Proceed by taking out chain tensioner assembly No.1 under the condition that crankshaft turning must stop while maintaining assembly position. Next step is to remove the V-ribbed belt tensioner assembly. Use engine hangers No.1 and No.2 along with bolts to torque at 38 Nm (387 kgf-cm, 30 ft. lbs.). Afterward remove the transverse engine mounting insulator through engine hanger attachment with chain hoist cutting of the insulator and removal of the engine mounting bracket right. The service technician must remove six sub-components: timing chain or belt cover sub-assembly, crankshaft position sensor plate No.1, chain tensioner slipper, chain vibration damper No.1 and chain sub-assembly. The installation procedure for No.2 chain sub-assembly includes turning the crankshaft counterclockwise by 90 degrees degrees before aligning the oil pump drive shaft gear and locking it in position while removing the nut, bolt and chain tensioner plate and spring. The installation process for No.2 chain sub-assembly requires positioning the crankshaft key to the left horizontal position while aligning mark links with timing marks and performing a temporary tightening of the oil pump drive shaft gear. Set down the crankshaft counterclockwise by 90 degrees to align the oil pump drive shaft gear before assembling a nut and torquing it to 30 Nm (301 kgf-cm, 22 ft. lbs.). Turn the crankshaft 90 degrees downward before aligning the key shaft to its peak. The technician installs chain vibration damper No.1 while torquing to 9.0 Nm (92 kgf-cm and 80 inch lbs.) before using Special Service Tool: 09309-37010 to position and install the sprocket at the correct timing marks. The chain tensioner slipper requires installation with 19 Nm (194 kgf-cm, 14 ft. lbs.) torque and positioning the "F" mark on crankshaft position sensor plate No.1 facing forward. The timing chain or belt cover sub-assembly installation requires all contact surfaces free of oil together with specified seal packing before utilizing 14 bolts and 2 nuts according to this torque procedure: Bolt A requires a torque of 9.0 Nm (92 kgf-cm, 80 inch lbs.), Bolt B needs 21 Nm (214 kgf-cm, 15 ft. lbs.), Bolt C requires 43 Nm (438 kgf-cm, 32 ft. lbs.) and Nut needs 9.0 Nm (92 kgf-cm, 80 inch lbs.). After installing the stud bolt to the drive belt tensioner at 10 Nm (102 kgf-cm) torque rating, add the V-ribbed belt tensioner assembly with torque set to 60 Nm (607 kgf-cm). Install transverse engine mounting bracket right with 3 bolts, torquing to 52 Nm (531 kgf-cm, 38 ft. lbs.), followed by the transverse engine mounting insulator right, raising the engine and installing it with 4 nuts, torquing to 95 Nm (969 kgf-cm, 70 ft. lbs.) for Bolt A and 87 Nm (888 kgf-cm, 64 ft. lbs.) for Bolt B. Reconnect the steering gear return hose clamp and install the engine mounting insulator rear with 2 nuts, torquing to 52 Nm (530 kgf-cm, 38 inch lbs.), and the engine mounting insulator front with 2 nuts, also torquing to 52 Nm (530 kgf-cm, 38 inch lbs.). The installer must first clean the contact regions before securing the oil pan sub-assembly with 12 bolts and two nuts by applying seal packing per the specifications and torquing the components to 9.0 Nm (92 kgf-cm, 80 inch lbs.). The service procedure includes installation of the crankshaft position sensor along with chain tensioner assembly No.1 at 9.0 Nm (92 kgf-cm, 80 inch lbs.), then the pulley bolt installation with Special Service Tools: 09213-54015 (91651-60855), 09330-00021 while aligning pulley set key for 170 Nm (1733 kgf-cm, 125 ft. lbs.) torque. Finally, install the cylinder head cover sub-assembly, ignition coil assembly, torquing to 9.0 Nm (92 kgf-cm, 80 inch lbs.), vane pump assembly, generator assembly, fan and generator V belt, engine mounting bracket No.2 right, torquing to 52 Nm (531 kgf-cm, 38 ft. lbs.), engine moving control rod with bracket, torquing to 64 Nm (653 kgf-cm, 47 ft. lbs.), engine mounting stay No.2 right, torquing to 64 Nm (653 kgf-cm, 47 ft. lbs.), exhaust pipe assembly front, front right wheel, torquing to 103 Nm (1,050 kgf-cm, 76 ft. lbs.), and hood sub-assembly, torquing to 13 Nm (133 kgf-cm, 10 ft. lbs.). The technician performs an oil addition to the engine system while inspecting areas for any signs of fluid leakage.