×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Corolla Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Starter Motor found

2003 Toyota Corolla Starter

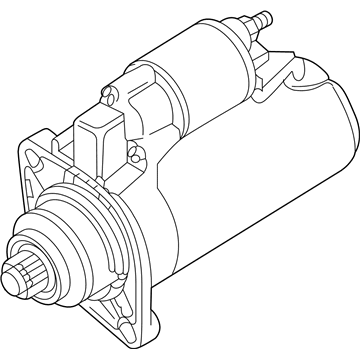

Part Number: 28100-0D080-84$95.68 MSRP: $132.80You Save: $37.12 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Reman Starter 1Zz-Fe; Starter Motor

- Item Weight: 10.40 Pounds

- Item Dimensions: 9.1 x 7.1 x 5.3 inches

- Condition: New

- SKU: 28100-0D080-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Corolla Starter Motor

Looking for affordable OEM 2003 Toyota Corolla Starter Motor? Explore our comprehensive catalogue of genuine 2003 Toyota Corolla Starter Motor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Corolla Starter Motor Parts Q&A

- Q: How to service and repair the starter motor on 2003 Toyota Corolla?A: The process of fixing the starter motor starts with separating the repair kit using wire disconnect and screw removal from the housing before extracting all components together with the spring and plunger. Start by detaching the starter commutator end frame cover with a screwdriver and follow this by removing the starter commutator end frame assembly with snap ring pliers to unfasten the snap ring and plate washer before taking off the two through bolts to free the starter yoke assembly with the commutator end frame assembly. Start by detaching the starter yoke assembly from the starter armature assembly and then disassemble the starter armature plate followed by the removal of the three planetary gears. An ohmmeter assessment of the armature starter assembly should be conducted for commutator segment continuity along with a ground continuity evaluation between the commutator and armature coil core. If inspection reveals problems replace the armature immediately. Before proceeding check the commutator surface for dirt or burn marks. Fix any issues with sandpaper (No.400) or a lathe and measure the circle runout with a dial indicator to confirm values do not exceed 0.05 mm (0.0020 in.). Also measure commutator length using vernier calipers to ensure standards of 3.3 mm (0.1299 in.) up to maximum length of 4.0 mm (0.1575 in.). The starter commutator end frame assembly should be inspected for continuity between brush holders and the measurement of brush holder length. The assembly requires replacement when continuity presents or the length reaches 4.0 mm (0.0787 in.). Check the starter center bearing clutch sub-assembly to see if gear teeth wear or damage is present while testing the starter clutch operation through rotation assessments. Check the pull-in and hold-in coils for electrical continuity within the repair service starter kit while ensuring the plunger moves efficiently; get a new replacement kit if any failures exist. The reassembly process begins with applying grease to the planetary gears and pin parts before installing three planetary gears while placing the cutout on the plate against the protrusion within the shock absorber. Secure the starter armature plate along with the armature assembly by applying grease to the washer plate and armature shaft before placing a new snap ring that should be shorter than 5.0 mm (0.1969 in.). Reinstall the starter commutator end frame cover before you place the starter yoke assembly in position then fasten the assembly to the frame with two through bolts which need to be torqued at 6.0 Nm (61 kgf.cm, 52 in.lbf). The last step includes applying grease to the plunger and hook followed by connection of the plunger hook to the drive lever, then installation of the plunger and return spring and final securement of the repair service starter kit with two screws torqued to 7.5 Nm (80 kgf.cm, 69 in.lbf) and nut greasing before connecting the lead wire to the terminal using a torqued nut at 6.5 Nm (66 kgf.cm, 58 in.lbf).