×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Corolla Crankshaft Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshaft Seals found

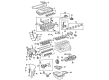

2003 Toyota Corolla Oil Seal, Front

Part Number: 90080-31049$9.91 MSRP: $13.79You Save: $3.88 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Seal, Type T Oil; Engine Crankshaft Seal, Front; Timing Cover Gasket; Multi-Purpose Seal; Timing Cover Seal; Crankshaft Seal; Front Seal; Timing Cover Oil Seal; Cover Seal; Oil Seal for Timing Chain/Belt.

- Manufacturer Note: (L)

- Position: Front

- Replaces: 90311-38059, 90080-31060

- Part Name Code: 11302A

- Item Weight: 0.50 Pounds

- Item Dimensions: 2.2 x 2.2 x 0.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 90080-31049

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Corolla Rear Main Seal

Part Number: 90311-76003$44.20 MSRP: $61.53You Save: $17.33 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal, Type T Oil; Engine Crankshaft Seal, Rear; Engine Crankshaft Seal; Crankshaft Seal

- Position: Rear

- Replaces: 90080-31059, 90311-76001, 90080-31050

- Item Weight: 1.90 Pounds

- Condition: New

- SKU: 90311-76003

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Corolla Crankshaft Seal

Looking for affordable OEM 2003 Toyota Corolla Crankshaft Seal? Explore our comprehensive catalogue of genuine 2003 Toyota Corolla Crankshaft Seal. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Corolla Crankshaft Seal Parts Q&A

- Q: How to replace a crankshaft seal on 2003 Toyota Corolla?A: The replacement process of crankshaft main bearing seal starts by removing both the manual transaxle assembly and automatic transaxle assembly. The first step requires removing 6 bolts from the clutch cover assembly before proceeding to remove the clutch disc assembly together with the flywheel sub-assembly. detach the flywheel by using the Special Service Tool: 09960-10010 (09962-01000, 09963-01000) to fasten the crankshaft and then disassemble the 8 bolts. Symmetrically uninstall both automatic transaxle drive plate and ring gear sub-assembly components. Use a knife to cut the oil seal lip before removing it with a tape-wrapped screwdriver when inspecting the crankshaft for damage while repairing it with sandpaper (#400). A new engine rear oil seal installation requires MP grease application to the lip while keeping it clean from foreign substances followed by Special Service Tool: 09223-15020, 09950-70010 (09951-07100) use for tapping it until it reaches the rear oil seal retainer edge. Finish by wiping off any remaining grease. Device 09960-10010 (09962-01000, 09963-01000) allows the crankshaft installation before applying adhesive (Part No. 0933-00070, Three Bond or equivalent) to bolts. Uniform bolt tightening to 49 Nm (500 kgf-cm, 36 ft. lbs.) occurs sequentially while marking bolts with paint and additional 90% retightening. Mount the clutch disc assembly by means of tool 09301-00210 before placing the clutch cover assembly. Tighten the attachment between the drive plate and ring gear by first repositioning the crankshaft through Special Service Tool: 09960-10010 (09962-01000, 09963-01000). Then thoroughly cleanse every bolt and hole before applying adhesive (Part No. 09330-00070, Three Bond or equivalent) and using a 88 Nm torque (897 kgf-cm, 65 ft. lbs.) on each bolt while applying it in a sequential order. Close by replacing the manual transaxle assembly together with the automatic transaxle assembly.