×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Corolla Cylinder Head Gasket

Engine Cylinder Head Gasket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head Gasket found

2003 Toyota Corolla Head Gasket

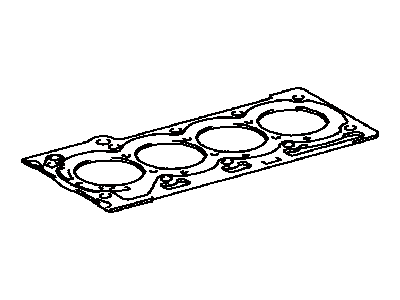

Part Number: 11115-22050$64.45 MSRP: $90.47You Save: $26.02 (29%)Ships in 1 Business DayProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Replaces: 11115-22030, 11115-22031, 11115-22040, 11115-22041

- Part Name Code: 11115

- Item Weight: 0.70 Pounds

- Item Dimensions: 25.2 x 8.8 x 0.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11115-22050

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Corolla Cylinder Head Gasket

Looking for affordable OEM 2003 Toyota Corolla Cylinder Head Gasket? Explore our comprehensive catalogue of genuine 2003 Toyota Corolla Cylinder Head Gasket. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Corolla Cylinder Head Gasket Parts Q&A

- Q: How to replace the cylinder head gasket on 2003 Toyota Corolla?A: Start by preventing gasoline from dripping during the cylinder head gasket replacement process so remove first the engine under cover on the right-hand side and drain the coolant. Start by removing the front wheel RH together with cylinder head cover No.2 through the process of unfastening 2 nuts and 2 clips and extracting the cover itself. Begin by removing the air cleaner hose thanks to 2 loosen clamp bolts then detaching the accelerator control cable assembly from its bracket by nut removal. The water by-pass hoses from the throttle body must be detached followed by EFI fuel pipe clamp separation and release of the fuel tube sub-assembly with Special Service Tool: 09268-21010. Detach the radiator hose inlet along with the heater inlet water hose from the cylinder head. Unwind the fan and generator V belt after loosening the V-ribbed belt tensioner but keep the hose attached to the vane pump assembly before separation. Proceed with removing the generator assembly and exhaust pipe assembly front section by unfastening both bolts while also dispatching the gasket. To remove the engine mounting insulator sub-assembly RH the technician first positions the PS oil pump reservoir out of way before installing a wooden block between the jack and engine then removes 4 bolts combined with 2 nuts. You must first remove the 5 clamps and 4 ignition coil connectors from the engine wire for disconnecting it prior to removing the ignition coil assembly. An operator can remove the cylinder head cover sub-assembly by disassembling all 9 bolts together with 2 seal washers and 2 nuts and 3 clamp brackets and also removing the ventilation hoses from the cylinder head cover. Place No. 1 cylinder at TDC compression position when both the crankshaft pulley timing mark "0" matches with the groove and both camshaft timing sprocket marks are in alignment. Extract the crankshaft pulley with Special Service Tool: 09960-10010 (09962-01000, 09963-01000) and proceed with elimination of the V-ribbed belt tensioner assembly, water pump assembly, transverse engine mounting bracket. Incomplete rotations of the crankshaft should occur without the chain tensioner when you remove the crank position sensor and chain tensioner assembly No.1. On the front of the engine remove the sequence of sub-assemblies which includes the timing chain or belt cover assembly and timing gear cover oil seal alongside crankshaft position sensor plate No.1 chain tensioner slipper and chain vibration damper No.1. Seize the timing chain while keeping it attached to the crankshaft timing gear while also safeguarding the engine configuration and obviating valve-piston interference. First disconnect all water and vacuum hoses from the intake manifold then remove both the oil level gauge sub-assembly and guide. Begin by separating the water by-pass pipe No.1 while using a sequence for loosening and removing the 19 cap bolts to extract the camshafts. First disconnect the camshaft timing oil control valve assembly with the manifold stay before you loose the cylinder head sub-assembly by sequential bolt removal of the 10 cylinder head bolts. Use the new cylinder head gasket by placing the Lot No. stamp at the upper section while maintaining correct installation orientation. Use the accepted specifications to measure the set bolts of the cylinder head before replacing any elements exceeding maximum length recommendations. Secure the cylinder head sub-assembly after applying engine oil to bolts and torquing them in sequence to 49 Nm (500 kgf-cm, 36 ft. lbs.) with front bolt marking while retightening at a 90-degree angle. Sequence all installations by first placing the manifold stay followed by the camshaft timing oil control valve assembly and then the camshafts to the specified torque values. Reconnect all hoses after installation of the water by-pass pipe No.1 followed by the oil level gauge guide and intake manifold which use new gaskets. Set the first cylinder to TDC/compression alignment once again while installing the timing chain along with the chain vibration damper which will precede installation of the chain tensioner slipper and crankshaft position sensor plate number 1. Mount the timing gear cover oil seal after ensuring its surface remains clean before putting in place the new timing chain or belt cover assembly while using appropriate seal packing. The installation of chain tensioner assembly must be combined with crank position sensor and transverse engine mounting bracket alongside water pump assembly and V-ribbed belt tensioner assembly which requires specific torque values during the procedure. The crankshaft pulley must receive installation according to torque requirements along with shared installation duties of the ignition coil assembly and engine wire sub-assemblies after cylinder head cover sub-assembly and seal packing insertion. The final step includes engine mounting insulator sub-assembly RH installation alongside front exhaust pipe assembly and vane pump assembly, generator assembly, and cylinder head cover No.2 where all components need proper torque specification. Physically return the right-hand front wheel followed by adding engine coolant while performing inspections for engine compression together with CO/HC testing and ignition timing checks as well as searching for leaks throughout the engine coolant system and oil.