×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Corolla Clutch Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Clutch Master Cylinders found

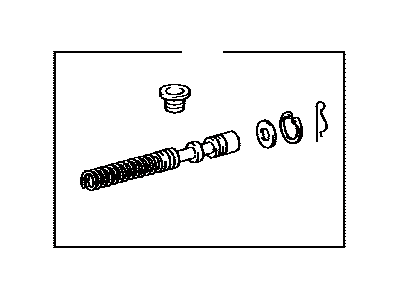

2002 Toyota Corolla Cylinder Kit, Clutch Master

Part Number: 04311-12110$42.65 MSRP: $59.36You Save: $16.71 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Kit Clutch; Clutch Master Cylinder

- Replaces: 04311-60150

- Part Name Code: 04311

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.1 x 2.6 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 04311-12110

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

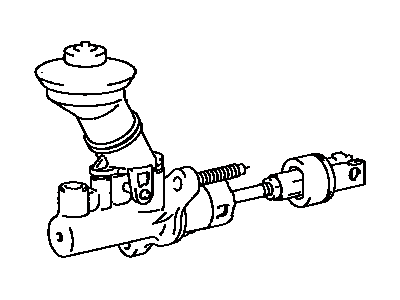

2002 Toyota Corolla Master Cylinder

Part Number: 31410-12381$154.15 MSRP: $218.22You Save: $64.07 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Master; Clutch Master Cylinder; Brake Master Cylinder; Cylinder Assembly, Clutch Master

- Replaces: 31410-12371, 31410-12380, 31410-12340, 31410-12370, 31410-12350, 31410-12330

- Part Name Code: 31410

- Item Weight: 1.50 Pounds

- Item Dimensions: 12.5 x 6.6 x 4.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 31410-12381

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Corolla Clutch Master Cylinder

Looking for affordable OEM 2002 Toyota Corolla Clutch Master Cylinder? Explore our comprehensive catalogue of genuine 2002 Toyota Corolla Clutch Master Cylinder. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Corolla Clutch Master Cylinder Parts Q&A

- Q: How to service and repair the Clutch Master Cylinder on 2002 Toyota Corolla?A: Service and repair the Clutch Master Cylinder by first removing the brake booster then drawing fluid through a syringe before disconnecting the clutch line using Special Service Tool: 09023-00100 while capturing fluid into a container. Begin the Clutch Master Cylinder repair by first removing the lower finish panel along with the lower insert, No. 2 heater to register duct and its attached clip and pin. After that remove the two mounting nuts to pull out the master cylinder. Finish the procedure by taking off the gasket. The clevis and boot need unlocking by loosening the lock nut before you drive out the slotted spring pin with a pin punch and hammer for tank reservoir removal. Finish by removing the push rod and washer through snap ring pliers until removing the snap ring. Proceed to remove the piston. All parts must get lithium soap base glycol grease treatment before installing the piston inside the cylinder and adding a new gasket alongside washer to the push rod assembly where it's necessary to install both the snap ring and boot. Position the reservoir tank along with a new grommet and fix its position with the slotted spring pin. Place a new gasket on the master cylinder before installing it with two mounting nuts torque to 12 Nm (120 kgf-cm, 9 ft. lbs.) and install the pin and clip afterward the No. 2 heater to register duct, lower insert, and lower finish panel. Use Special Service Tool 09023-00100 to connect the clutch line while torquing it to 13 Nm with a 300 mm (11.81 inch) torque wrench having a fulcrum length of 133 kgf-cm (133 kgf-cm, 10 ft. lbs.). The clutch maintenance concludes with a fluent brake fluid addition to the reservoir then bleeds the system and restores the booster while readjusting the pedal height to check for fluid leakage.