×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Celica Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Shock Absorbers found

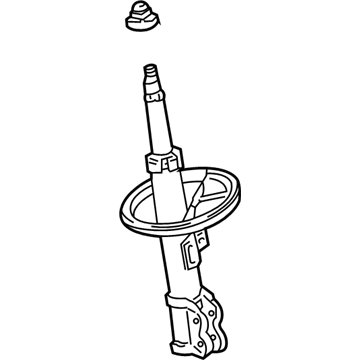

2002 Toyota Celica Strut, Front Passenger Side

Part Number: 48510-80324$125.13 MSRP: $177.13You Save: $52.00 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Suspension Strut, Front Right; Shock Absorber

- Position: Front Passenger Side

- Replaces: 48510-80072, 48510-80220, 48510-80221, 48510-80071, 48510-29755, 48510-29756, 48510-80325

- Item Weight: 1.40 Pounds

- Item Dimensions: 26.4 x 8.4 x 7.6 inches

- Condition: New

- SKU: 48510-80324

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

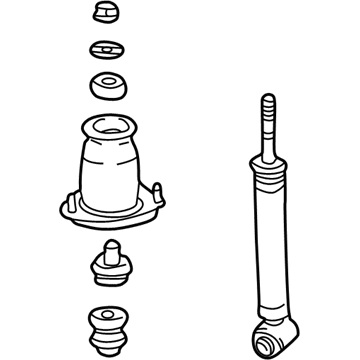

2002 Toyota Celica Shock Absorber, Rear Passenger Side

Part Number: 48530-80331$100.12 MSRP: $140.54You Save: $40.42 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Set, Rear Right-Hand; Shock Absorber, Rear; Suspension Strut Assembly Kit; Complete Strut Kit; Complete Strut; Strut; Absorber Assembly, Shock, Rear Passenger Side; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48530-2B830

- Position: Rear Passenger Side

- Replaces: 48530-29775

- Item Weight: 4.70 Pounds

- Item Dimensions: 26.1 x 6.7 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-80331

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Celica Strut, Front Driver Side

Part Number: 48520-80101$125.13 MSRP: $177.13You Save: $52.00 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Suspension Strut, Front Left; Shock Absorber

- Position: Front Driver Side

- Replaces: 48520-29675, 48520-80046, 48520-80102, 48520-29465, 48520-29466, 48520-29665, 48520-80047

- Item Weight: 1.40 Pounds

- Item Dimensions: 27.1 x 8.5 x 7.6 inches

- Condition: New

- SKU: 48520-80101

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Celica Shock Absorber

Looking for affordable OEM 2002 Toyota Celica Shock Absorber? Explore our comprehensive catalogue of genuine 2002 Toyota Celica Shock Absorber. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Celica Shock Absorber Parts Q&A

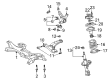

- Q: How to Service and Repair a Shock Absorber in a Suspension Strut on 2002 Toyota Celica?A: Service and repair of the suspension strut starts by compressing the coil spring using tool 09727-30021 (09727-00010, 09727-00021, 09727-00031) but prevent using impact wrenches to protect the tool from damage. Use a 6 mm hexagon wrench to hold the piston rod and then remove the nut before taking out the washer, cushion, spring bracket, upper insulator and suspension support, spring bumper and coil spring. Inspect the shock absorber by applying pressure to the rod and extending it for abnormal resistance symptoms or odd sounds. The shock absorber needs immediate replacement in case of any such problems. After drilling a hole through the cylinder while the shock absorber rod is fully extended there must be caution due to the flying chips that accompany the colorless odorless non-poisonous gas. Reassemble the shock absorber after compressing the coil spring using Special Service Tool: 09727-30021 (09727-00010, 09727-00021, 09727-00031) and pushing the spring lower end into the seat gap. Set the upper insulator to the spring bracket before properly positioning it on the suspension support together with the spring bumper. First place the washer and cushion in position before tightening the center nut briefly then removing the Special Service Tool to verify spring bracket orientation and finish by tightening the nut to 56 Nm (571 kgf-cm, 41 ft. lbs.) using a 6 mm hexagon wrench on the piston rod.