×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2002 Toyota Avalon Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Control Arms found

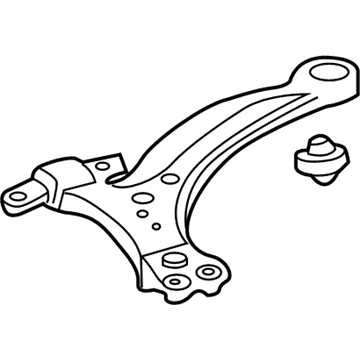

2002 Toyota Avalon Lower Control Arm, Driver Side

Part Number: 48069-07030$193.96 MSRP: $276.93You Save: $82.97 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left; Control Arm Assembly; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Suspension Control Arm; Control Arm

- Position: Lower Driver Side

- Part Name Code: 48069

- Item Weight: 7.60 Pounds

- Item Dimensions: 19.7 x 3.3 x 15.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48069-07030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Avalon Lower Control Arm, Passenger Side

Part Number: 48068-07030$193.96 MSRP: $276.93You Save: $82.97 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm; Control Arm Assembly; Control Arm; Arm Sub-Assembly, Front Suspension, Lower Passenger Side

- Position: Passenger Side

- Part Name Code: 48068

- Item Weight: 8.10 Pounds

- Item Dimensions: 19.3 x 3.2 x 15.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48068-07030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Avalon Control Arm

Looking for affordable OEM 2002 Toyota Avalon Control Arm? Explore our comprehensive catalogue of genuine 2002 Toyota Avalon Control Arm. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2002 Toyota Avalon Control Arm Parts Q&A

- Q: How to service and repair the rear control arm on 2002 Toyota Avalon?A: The service and repair of the rear control arm starts with wheel removal along with torque application at 103 Nm (1,050 kgf-cm, 76 ft. lbs.). After disconnecting the parking brake cable from its bolt you should remove the center exhaust hose and the strut rod. Then take off the 2 bolts with 113 Nm (1,150 kgf-cm, 83 ft. lbs.) torque while avoiding turning the nut. To reinstall, first maintain suspension stability before applying the torque to the bolts. Install the lower suspension arm No. 2 after taking off 3 nuts, the suspension arm washer, and washer and tightening them to 181 Nm (1,850 kgf-cm, 134 ft. lbs.) while making sure the paint mark sits in the correct rear orientation. A jack should support the suspension member during the removal process when 4 nuts, 2 bolts, and 8 suspension member stoppers are detached. The torque should be set to 51 Nm (520 kgf-cm, 38 ft. lbs.) for A type brackets and 38 Nm (390 kgf-cm, 28 ft. lbs.) for B type brackets. After lowering the suspension member remove 2 bolts and washers together with the No. 1 lower suspension arm by maintaining the paint mark in the rear position. The disassembly process requires users to first loosen two lock nuts before they can turn the adjusting tube to separate the No. 2 lower suspension arm followed by removing the lock nuts. Install the two lock nuts then use the adjusting tube to arrange the No. 2 lower suspension arm while keeping A and B lengths matching to within 3.0 mm (0.118 inch) of equal length and set the arm to 512.3 mm (20.169 inch). Lock the 2 nuts with moderate torque at first then tighten them to 56 Nm (570 kgf-cm, 41 ft lbs) after performing the wheel alignment correction. The procedure ends with checking wheel alignment after the installation process completes in reverse order to removal.