×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Sienna Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Calipers found

- Product Specifications

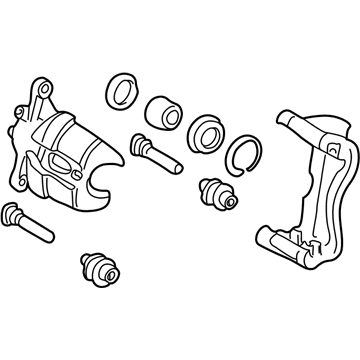

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Position: Driver Side

- Replaces: 47750-06050

- Part Name Code: 47750

- Item Weight: 11.30 Pounds

- Item Dimensions: 9.9 x 7.5 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-08010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Replaces: 47730-06050

- Part Name Code: 47730

- Item Weight: 12.30 Pounds

- Item Dimensions: 10.1 x 7.7 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-08010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Sienna Brake Caliper

Looking for affordable OEM 2000 Toyota Sienna Brake Caliper? Explore our comprehensive catalogue of genuine 2000 Toyota Sienna Brake Caliper. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Sienna Brake Caliper Parts Q&A

- Q: How to service and repair the brake caliper on 2000 Toyota Sienna?A: Service and repair of the brake caliper starts with using a screwdriver to take out the cylinder boot set ring and cylinder boot. After inserting cloth between the piston and caliper you should use compressed air to extract the piston from the cylinder while keeping your fingers away from the piston. Begin the process by extracting the piston seal with a screwdriver and later removing the 2 sliding pins from the torque plate keeping in mind that the reassembly sequence will place the sliding pin with bushing in the lower section and the plain pin above. Compounding the 2 dust boots requires a screwdriver and hammer before reinstallation through the use of a 24 mm socket and hammer to mount new dust boots with precise positioning of the metal plate in the torque plate. Disc thickness measurement is performed with a micrometer for inspection purposes. The accepted standard thickness is 28.0 mm (1.102 inch) and the minimum threshold is 26.0 mm (1.024 inch). The disc should be replaced when either thickness limit is reached or when it contains scores or uneven wear. The maximum allowable runout using a dial indicator at 10 mm (0.39 inch) from the disc outside edge should be set at 0.05 mm (0.0020 inch); if runout exceeds this value check bearing play together with axle hub runout to determine whether disc requires adjustment or grinding. The disc should be set to 1/5 rotation beyond the initial position when reinstalling on the hub before torquing hub nuts to 77 ft. lbs (1,050 kgf-cm, 104 Nm). Succeeding remeasurement of disc runout should consist of recording the disc position that produces the lowest runout reading below 0.05 mm (0.0020 inch). Another measurement follows to confirm the selected disc position unless another disc needs replacement. Reassemble the parts by putting on the torque plate followed by tightening the mounting bolts to 107 Nm (1,090 kgf-cm, 79 ft. lbs.). Implement this process by conducting disassembly in reverse order and lubricate the specified parts with lithium soap base glycol grease and disc brake grease.