×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Camry Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Axle Shafts found

- Product Specifications

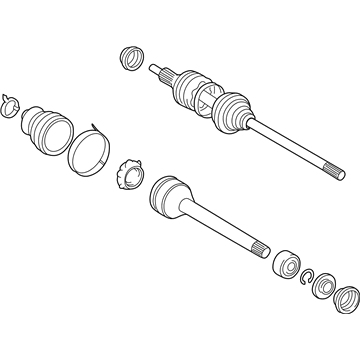

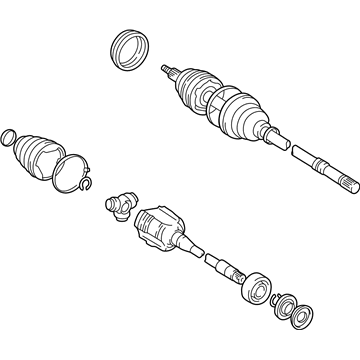

- Other Name: REMAN CV AXLE, RH; CV Axle Assembly; Axle Shaft

- Position: Passenger Side

- Item Weight: 14.50 Pounds

- Item Dimensions: 31.0 x 5.3 x 5.4 inches

- Condition: New

- SKU: 43410-06070-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Reman Cv Axle, Left-Hand; CV Axle Assembly, Front Left; CV Axle Assembly; GSP Cv Axle; Axle Shaft

- Position: Driver Side

- Item Weight: 14.90 Pounds

- Item Dimensions: 8.6 x 4.3 x 4.2 inches

- Condition: New

- SKU: 43420-06060-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: REMAN CV AXLE, LH; CV Axle Assembly; Axle Shaft

- Position: Driver Side

- Replaces: 43420-06070

- Item Weight: 14.50 Pounds

- Item Dimensions: 32.2 x 5.3 x 5.4 inches

- Condition: New

- SKU: 43420-06070-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

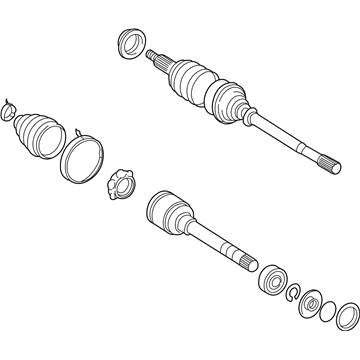

- Product Specifications

- Other Name: Reman Cv Axle, Right-Hand; CV Axle Assembly, Front Right; CV Axle Assembly; GSP Cv Axle; Axle Shaft

- Position: Passenger Side

- Item Weight: 14.00 Pounds

- Item Dimensions: 30.7 x 7.5 x 6.6 inches

- Condition: New

- SKU: 43410-06060-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Reman Cv Axle, Left-Hand; CV Axle Assembly, Front Left; CV Axle Assembly; GSP Cv Axle; Axle Shaft

- Position: Driver Side

- Item Weight: 14.40 Pounds

- Item Dimensions: 31.0 x 7.8 x 6.7 inches

- Condition: New

- SKU: 43420-06050-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Reman Cv Axle, Right-Hand; CV Axle Assembly, Front Right; CV Axle Assembly; GSP Cv Axle; Axle Shaft

- Position: Passenger Side

- Item Weight: 22.00 Pounds

- Item Dimensions: 30.4 x 7.8 x 6.6 inches

- Condition: New

- SKU: 43410-06050-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left, Front Right; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; CV Axle Assembly

- Position: Passenger Side

- Replaces: 43410-06100, 43410-06030, 43410-06040, 43410-06090

- Part Name Code: 43410

- Item Weight: 14.60 Pounds

- Item Dimensions: 31.3 x 8.0 x 6.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43410-06180

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Position: Driver Side

- Replaces: 43420-06040, 43420-06030, 43420-06100, 43420-06090

- Part Name Code: 43420

- Item Weight: 20.70 Pounds

- Item Dimensions: 30.4 x 7.8 x 6.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43420-06180

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Camry Axle Shaft

Looking for affordable OEM 2000 Toyota Camry Axle Shaft? Explore our comprehensive catalogue of genuine 2000 Toyota Camry Axle Shaft. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Camry Axle Shaft Parts Q&A

- Q: How to remove and install the axle shaft on 2000 Toyota Camry?A: The first step toward removing or installing an axle shaft begins by supporting the hub bearing with Special Service Tool: 09608-16042 (09608-02021, 09608-02041) since this tool protects the components from damage during vehicle weight application. You need to remove the front wheel along with the front fender apron seal and tighten them to 103 Nm (1,050 kgf.cm, 76 ft. lbs.). Start by dismissing the drive shaft lock nut by first turning out the cotter pin and lock cap before removing it with your brakes engaged at 294 Nm (3,000 kgf.cm, 217 ft. lbs.). The technician drains either M/T oil (M/T) or ATF (A/T) before untethering the tie rod end from the steering knuckle along with disconnecting the lower ball joint from the bottom suspension arm. The drive shaft connection to the axle hub needs to be removed by using a plastic hammer on a protected drive shaft boot with cloth. This action pushes the front axle hub outward to achieve drive shaft separation. To remove and install the LH drive shaft you must apply a brass bar alongside a hammer as well as coat the inboard joint shaft and differential case sliding surface with gear oil and ensure the snap ring faces downward while confirming the inboard joint shaft aligns with the pinion shaft and conducting an axial play examination for between 2 to 3 mm (0.08 - 0.12 inch) before verifying hand-removal resistance. A screwdriver should be used to remove the snap ring from around the inboard joint shaft. To install the RH drive shaft begin by removing the bearing lock bolt at 32 Nm torque followed by removing the snap ring with pliers while coating the gear oil on both the inboard joint shaft and differential case sliding surface. Following the installation step you should conduct a test of both ABS speed sensor signals and front wheel alignment alignment.