×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Avalon Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Starter Motor found

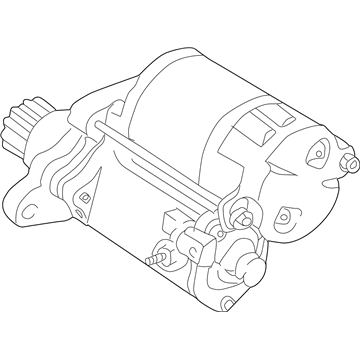

2000 Toyota Avalon Starter Assembly

Part Number: 28100-74260-84$158.04 MSRP: $222.38You Save: $64.34 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: REMAN STARTER ASSY; Starter Motor; Starter

- Replaces: 28100-03100, 28100-74260

- Item Weight: 15.60 Pounds

- Item Dimensions: 13.8 x 6.5 x 6.3 inches

- Condition: New

- SKU: 28100-74260-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Avalon Starter Motor

Looking for affordable OEM 2000 Toyota Avalon Starter Motor? Explore our comprehensive catalogue of genuine 2000 Toyota Avalon Starter Motor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Avalon Starter Motor Parts Q&A

- Q: How to service and repair the starter motor on 2000 Toyota Avalon?A: Begin the starter motor service repair by taking off the dust protector then unfasten the lead wire from the magnetic switch terminal while loosening the nut to 5.9 Nm (60 kg.cm, 52 in.lb). The field frame extraction process begins by unscrewing the two through bolts with a specified torque value until the field frame and armature can be pulled out together. The protrusion of the field frame corresponding to the indentation of magnetic switch must be aligned throughout this step. Install the new field frame O-ring by following the previous procedure of removal. Remove the starter housing, clutch assembly, and gear through the process of unscrewing two screws at 5.9 Nm (60 kg.cm, 52 in.lb) torque level. Next, extract the starter housing followed by the clutch assembly, then proceed with the return spring, idler gear, and bearing removal. A magnetic finger tool should be used to remove the steel ball through the clutch shaft opening. You need to remove four brushes from the brush holder by taking out the screws and end cover from the field frame at 1.5 Nm (15 kg.cm, 13 in.lb) torque while maintaining the positive lead wires free from ground. A vice equipped with a brass bar allows the disassembly of clutches by lowering the pinion gear then striking the stop collar with a gentle blow from a plastic-faced hammer until the snap ring frees for removal of stop collar, pinion gear and compression spring. Reassembly starts with fixing the compression spring along with the clutch shaft to the starter clutch before re-attaching the starter clutch to the starter housing followed by installation of the spring retainer and compression spring and pinion gear and stop collar making sure the snap ring is properly positioned. Special Service Tool: 09286-46011 helps remove the front bearing before using Special Service Tool: 09820-00030 to press in a new one while observing proper installation direction. The process needs to be executed again for the rear bearing installation. Inspection of the magnetic switch terminals starts by removing three bolts and end cover and gasket and plunger components before checking the contact plate wear depth because excessive 0.9 mm (0.035 in.) depth requires replacement. The necessary parts from terminals C and 30 require removal using Special Service Tool: 09810-38140 before new terminal kit parts are installed while maintaining proper insulator and wave washer orientation. To tighten the terminal nuts use Special Service Tool: 09810-38140 while applying a wooden block to press down the contact plate at 981 N (100 kg, 221 lb). Complete the process by tightening the nuts to 17 Nm (173 kg.cm, 12 ft.lb). Reattach the plunger and new gasket followed by the end cover and its three bolts while tightening them to 2.5 Nm (25 kg.cm, 22 in.lb). The manufacturing process requires the technician to perform assembly in the opposite order of disassembly while applying high-temperature grease on bearings, springs, steel ball and gears.