×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

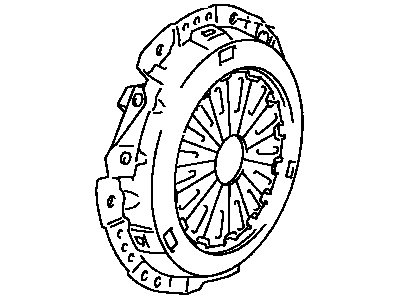

OEM Toyota Tacoma Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Pressure Plates found

Toyota Tacoma Pressure Plate

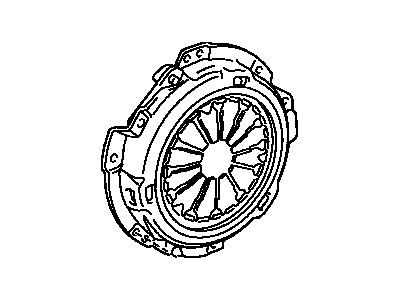

Part Number: 31210-35310$239.75 MSRP: $342.30You Save: $102.55 (30%)Ships in 1-3 Business Days

Toyota Tacoma Pressure Plate

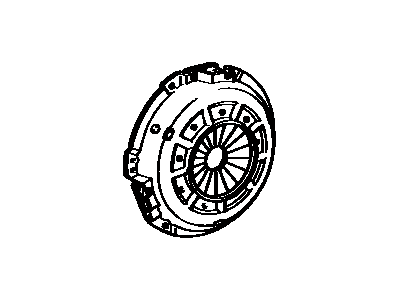

Part Number: 31210-26172$181.96 MSRP: $259.80You Save: $77.84 (30%)Ships in 1-2 Business DaysToyota Tacoma Pressure Plate

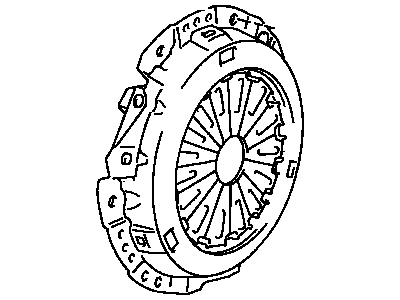

Part Number: 31210-60280$237.88 MSRP: $339.64You Save: $101.76 (30%)Ships in 1-2 Business DaysToyota Tacoma Pressure Plate

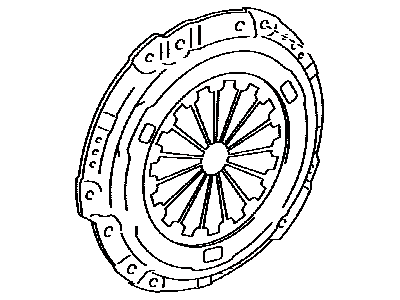

Part Number: 31210-35291$181.26 MSRP: $258.80You Save: $77.54 (30%)Ships in 1-3 Business DaysToyota Tacoma Pressure Plate

Part Number: 31210-04083$226.81 MSRP: $323.84You Save: $97.03 (30%)Ships in 1-3 Business Days

Toyota Tacoma Pressure Plate

Choose genuine Pressure Plate that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Pressure Plate for your Toyota Tacoma? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tacoma parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Tacoma Pressure Plate Parts and Q&A

- Q: How to service and repair the pressure plate on Toyota Tacoma?A:Service and repair of the pressure plate begins by removing the transmission from the engine then disconnecting the clutch cover and disc by marking it up with matchmarks between the flywheel and clutch cover while loosening each bolt set by one turn at a time until spring tension is reduced. Carefully remove the clutch cover with the attached Clutch Disc while avoiding dropping the disc. The third step requires the removal of transmission components which include the boot together with the release bearing and fork. Inspect the clutch disc through an evaluation of rivet head depth that should be a minimum of 0.3 mm (0.012 inch) to determine if replacement is needed. Test the runout distance of the clutch disc with a dial indicator for no more than 0.8 mm (0.031 inch) and analyze the flywheel for no greater than 0.1 mm (0.004 inch) runout before making replacements as necessary. Inspect the pilot bearing by turning it by hand; if it sticks or has resistance, replace it by removing the 2 bolts at opposite points, using Special Service Tool: 09303-35011 to remove the pilot bearing, and then using Special Service Tool: 09300-30012 and a hammer to install the new pilot bearing, ensuring it rotates smoothly before installing 2 new bolts with specified torque values: 2RZ-FE Engine: 88 Nm (900 kgf-cm, 65 ft. lbs.), 3RZ-FE Engine: 26.5 Nm (270 kgf-cm, 19 ft. lbs.), and 5VZ-FE Engine: 85 Nm (850 kgf-cm, 63 ft. lbs.). Measuring the diaphragm spring for wear requires assessment of maximum depth at 0.6 mm (0.024 inch) and maximum width at 5.0 mm (0.197 inch), with replacement needed for both specifications. Inspection of the release bearing includes manual rotation; replacement should be performed if necessary. Place the clutch disc and clutch cover on the flywheel with Special Service Tool: 09301-00110. Realign the matchmarks while torquing the clutch cover bolts to 19 Nm (195 kgf-cm, 14 ft. lbs.). Then temporarily fasten the No. 1 and No. 2 bolts. Perform clockwise and counterclockwise movements on the diaphragm spring tip with the aid of a dial indicator. Verify a maximum non-alignment reading below 0.5 mm (0.020 inch) and adjust using Special Service Tool: 09333-00013 if required. The maintenance task includes applying 100 grams of grease part number 08887-01706 NLGI No. 2 molybdenum disulphide lithium base grease to three contact points of the release fork hub and push rod and release fork pivot point. Additionally, clutch spline grease should be applied to the clutch disc spline. Reinstall the transmission to the engine after fitting its boot followed by release bearing and fork installation.