×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

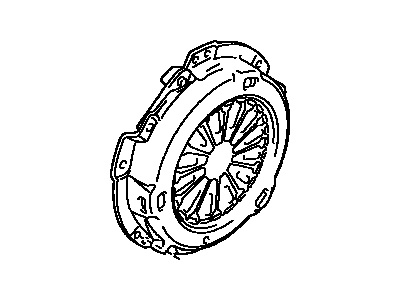

OEM Toyota MR2 Spyder Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Pressure Plate found

Toyota MR2 Spyder Pressure Plate

Part Number: 31210-17041$165.43 MSRP: $234.19You Save: $68.76 (30%)Ships in 1-3 Business Days

Toyota MR2 Spyder Pressure Plate

Choose genuine Pressure Plate that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Pressure Plate for your Toyota MR2 Spyder? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota MR2 Spyder parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

As a vital part of the clutch assembly the Toyota MR2 Spyder Pressure Plate offers dependable performance across multiple models of this vehicle series. The Pressure Plate acts as the primary mechanism which connects and disconnects the clutch disc from the flywheel to enable smooth power transmission between engine and transmission. The driver can perform gear changes easily through clutch disc release from the Pressure Plate when pressing the clutch pedal thus improving both driving safety and efficiency. The Toyota MR2 Spyder operates using two main types of Pressure Plates which consist of diaphragm style and lever style. The diaphragm style Pressure Plate equipped with a cone-shaped Belleville spring operates with reduced pedal resistance while enabling smooth engagement thus it works well for regular driving situations. By design the lever style enables high-end performance yet it remains an essential part of the entire Toyota MR2 Spyder Pressure Plate collection. Released from 1999 to 2007 on different releases of the MR2 Spyder convertible sports car the Pressure Plate maintains compatibility while enhancing vehicle performance. The Toyota MR2 Spyder performance improves dramatically through its Pressure Plate which delivers performance and safety improvements to its 1.8 L 1ZZ-FED inline 4-cylinder engine. The Toyota MR2 Spyder Pressure Plate distinguishes itself as an automotive market standout because of its unique composition and operational features which enable drivers to reach maximum potential in their model.

Toyota MR2 Spyder Pressure Plate Parts and Q&A

- Q: How to service and repair the pressure plate on Toyota MR2 Spyder?A:The pressure plate service process begins by taking out the engine-mounted transaxle followed by clutch cover removal along with Clutch Disc extraction using bolt matchmarks until spring tension releases allowing a careful clutch cover and clutch disc retrieval without clutch disc drop. The service starts with release bearing separation from the fork before individual removal of both components. The final steps include release fork support and boot extraction. Vernier calipers should measure the depth of clutch disc rivet heads for 0.3 mm (0.012 inch) minimally; replace the disc when measurement falls below this standard. A dial indicator allows inspection of clutch disc runout without exceeding 0.8 mm (0.031 inch) while the inspection of flywheel runout should not exceed 0.1 mm (0.004 inch) leading to a new flywheel replacement. When measuring the diaphragm spring for wear it must not exceed limits of 0.5 mm (0.020 inch) depth and 6.0 mm (0.236 inch) width before replacing the clutch cover. When performing visual inspection of the release bearing turn it by hand with axial force applied and if wear symptoms are detected then replace it. When installing the clutch disc, use Special Service Tool: 09301-00210 to mount it on the flywheel. Then position the clutch cover and flywheel matchmarks correctly before tightening the 6 bolts in sequence to 19 Nm (195 kgf-cm, 14 ft. lbs.) while making sure the disc maintains center position. A dial indicator should be used to examine diaphragm spring tip alignment with a maximum permissible non-alignment of 0.5 mm (0.020 inch); Special Service Tool: 09333-00013 can be used for any required adjustments. Use the boot and support the release fork within the transaxle. Apply release hub grease (Part No. 08887-01806 or equivalent) to the release fork and hub contact and release fork and push rod contact and release fork pivot points. Finally, impose clutch spline grease (Part No. 08887-01706 or equivalent) to the input shaft spline. Install the release bearing and fork to the transaxle before you reposition the transaxle to the engine.