×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2007 Toyota Tundra Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Drive Shafts found

2007 Toyota Tundra Drive Shaft

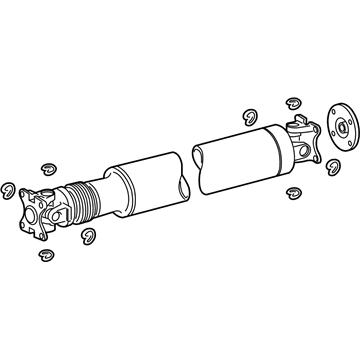

Part Number: 37100-0C155$1092.09 MSRP: $1600.47You Save: $508.38 (32%)Product Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37100-0C150, 37100-0C153, 37100-0C154

- Part Name Code: 37100

- Item Weight: 43.90 Pounds

- Item Dimensions: 89.8 x 7.4 x 7.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 37100-0C155

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37100-0C175$1504.43 MSRP: $2204.77You Save: $700.34 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37100-0C170, 37100-0C173, 37100-0C174

- Condition: New

- SKU: 37100-0C175

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37100-0C125$1187.65 MSRP: $1740.52You Save: $552.87 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37100-0C120, 37100-0C124, 37100-0C122, 37100-0C121

- Item Weight: 42.00 Pounds

- Item Dimensions: 101.0 x 7.3 x 6.2 inches

- Condition: New

- SKU: 37100-0C125

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37100-0C184$1099.01 MSRP: $1610.62You Save: $511.61 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37100-0C180

- Condition: New

- SKU: 37100-0C184

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37100-0C135$1015.02 MSRP: $1487.52You Save: $472.50 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37100-0C130, 37100-0C134

- Condition: New

- SKU: 37100-0C135

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37100-0C165$1129.31 MSRP: $1655.02You Save: $525.71 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37100-0C160, 37100-0C163, 37100-0C164

- Part Name Code: 37100

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 37100-0C165

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37100-0C145$1047.82 MSRP: $1535.60You Save: $487.78 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37100-0C144, 37100-0C141, 37100-0C142, 37100-0C140

- Part Name Code: 37100

- Item Weight: 15.40 Pounds

- Item Dimensions: 33.4 x 7.0 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 37100-0C145

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

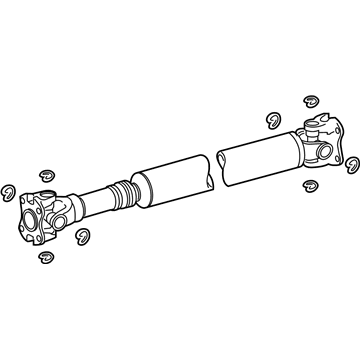

Part Number: 37100-0C106$960.77 MSRP: $1408.01You Save: $447.24 (32%)Product Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37100-0C105, 37100-0C103, 37100-0C104, 37100-0C101, 37100-0C102, 37100-0C100

- Part Name Code: 37100

- Item Weight: 54.50 Pounds

- Item Dimensions: 105.0 x 7.1 x 7.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 37100-0C106

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37110-0C115$746.82 MSRP: $1094.47You Save: $347.65 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37110-0C113, 37110-0C114, 37110-0C110

- Condition: New

- SKU: 37110-0C115

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37110-0C086$741.48 MSRP: $1086.65You Save: $345.17 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37110-0C083, 37110-0C081, 37110-0C080, 37110-0C082, 37110-0C085

- Item Weight: 14.40 Pounds

- Item Dimensions: 33.4 x 6.9 x 5.4 inches

- Condition: New

- SKU: 37110-0C086

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37110-0C095$732.29 MSRP: $1073.18You Save: $340.89 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37110-0C094, 37110-0C090

- Item Weight: 15.70 Pounds

- Item Dimensions: 34.4 x 6.7 x 5.5 inches

- Condition: New

- SKU: 37110-0C095

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37110-0C105$649.89 MSRP: $952.42You Save: $302.53 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37110-0C100, 37110-0C104

- Part Name Code: 37110

- Item Weight: 15.00 Pounds

- Item Dimensions: 34.0 x 6.9 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 37110-0C105

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Part Number: 37110-0C125$762.21 MSRP: $1117.03You Save: $354.82 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Drive Shaft Assembly

- Replaces: 37110-0C121, 37110-0C120, 37110-0C123

- Condition: New

- SKU: 37110-0C125

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft, Front

Part Number: 37140-0C072$390.20 MSRP: $571.85You Save: $181.65 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller, Front

- Position: Front

- Replaces: 37140-0C070, 37140-0C071, 37140-0C080

- Part Name Code: 37140

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 37140-0C072

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft Assembly, Propeller; Driveshaft

- Item Weight: 25.10 Pounds

- Condition: New

- SKU: 37100-0C143

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Item Weight: 26.30 Pounds

- Condition: New

- SKU: 37100-0C114

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Tundra Drive Shaft

Looking for affordable OEM 2007 Toyota Tundra Drive Shaft? Explore our comprehensive catalogue of genuine 2007 Toyota Tundra Drive Shaft. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2007 Toyota Tundra Drive Shaft Parts Q&A

- Q: How to service and repair the Drive Shaft assembly on 2007 Toyota Tundra?A: Service or repair work on 2WD vehicles starts by removing the 2 Joint Type propeller shaft assembly through flange matchmark placement followed by removal of 4 bolts and 4 nuts to disconnect the differential side of the propeller shaft. The Special Service Tool 09325-40010 needs to enter the transmission of the A750E to stop transmission fluid leakage whereas the Special Service Tool 09325-60010 is suitable for the AB60E. To perform the 3 Joint Type removal, use the same steps while taking care to place matchmarks before removing these specific bolts with washers and deploying the appropriate special service tool to stop oil leakage. Disassemble the universal joint spider bearing of the rear propeller shaft by using Special Service Tool: 09332-25010 while first marking both the propeller shaft and universal joint yoke then tapping the spider bearing before removing snap rings for extraction. Use a dial indicator to check propeller shaft assembly runout where 1.02 mm (0.0402 inch) maximum runout applies to the 2 Joint Type and 0.61 mm (0.0240 inch) for the intermediate shaft and 1.02 mm (0.0402 inch) for the propeller shaft. Check the spider bearing for wear and measure its axial play against specification 0.05 mm (0.00197 inch). To complete the reassembly add the center support bearing assembly then lubricate with MP grease alongside matching mark realignment before tightening the lock nut to 128 Nm (1305 kgf-cm, 94 ft. lbs.). Start by taking out the special service tools and insert the sleeve yoke into the transmission while lining up the matchmarks and bolt and nut components together to a torque level of 70 Nm (714 kgf-cm, 52 ft. lbs.). Before concluding check the center support bearing assembly for oil leakage.