×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2007 Toyota Highlander Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Starter motors found

2007 Toyota Highlander Starter

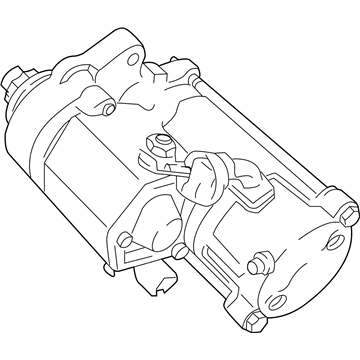

Part Number: 28100-20020-84$156.25 MSRP: $219.85You Save: $63.60 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Replaces: 28100-20020

- Item Weight: 7.20 Pounds

- Item Dimensions: 13.8 x 6.5 x 6.2 inches

- Condition: New

- SKU: 28100-20020-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Highlander Starter

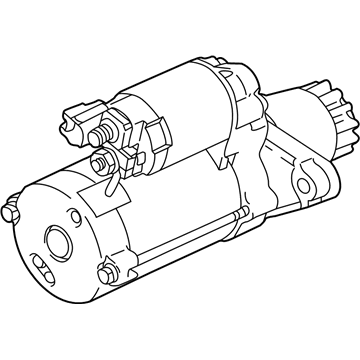

Part Number: 28100-28041-84$166.32 MSRP: $234.13You Save: $67.81 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Replaces: 28100-28040, 28100-28041

- Item Weight: 7.40 Pounds

- Item Dimensions: 13.5 x 6.4 x 6.3 inches

- Condition: New

- SKU: 28100-28041-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2007 Toyota Highlander Starter Motor

Looking for affordable OEM 2007 Toyota Highlander Starter Motor? Explore our comprehensive catalogue of genuine 2007 Toyota Highlander Starter Motor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2007 Toyota Highlander Starter Motor Parts Q&A

- Q: How to service and repair the starter motor on 2007 Toyota Highlander?A: The starter motor servicing starts with magnetic switch assembly nut removal and lead wire disconnection then moves to the magnetic switch screws removal from drive housing before fully removing it along with spring and plunger parts from the drive housing. The starter yoke assembly can be removed by discharging the two through bolts then extracting the yoke assembly with the commutator end frame before separating the yoke from the end frame. Use a screwdriver to first remove the starter armature plate from the yoke before disassembling the starter commutator end frame cover from it. Snap ring pliers are needed to detach the snap ring and plate washer while removing the armature from the commutator end frame. The drive housing needs to have its three planetary gears extracted. Apply grease to all rotational components of the planetary gear and pin afterward installing three planetary gears onto the planetary shaft. In order to install the armature on the starter commutator end frame through the commutator end, first apply grease to the plate washer and armature shaft followed by utilization of snap ring pliers to apply a new snap ring on the plate washer while using a vernier caliper to verify that the snap ring length does not surpass 5.0 mm (0.197 inches). Position the starter commutator end frame cover onto its respective frame and adjust the keyway of the starter plate to fit the key located inside the field frame before mounting. Mount the rubber end frame component into the opening of the yoke before making the attachment between the end frame and yoke. Fasten the protrusion of the yoke through the drive housing cutout using the 2 through bolts and tighten them to 6.0 N.m (61 kgf.cm, 53 in.lbf). Significantly spread grease on the plunger and hook before hanging the plunger hook of the magnetic switch to the drive lever. Put in the plunger and return spring and secure the magnetic switch using 2 screws torqued to 7.5 N.m (76 kgf.cm, 66 in.lbf). The last step includes connecting the magnetic switch lead wire with a nut and torquing it to 10 N.m (102 kgf.cm, 7 ft.lbf).