×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Tundra Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Water Pump found

2006 Toyota Tundra Water Pump

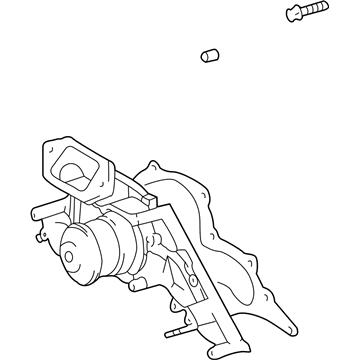

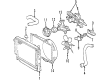

Part Number: 16100-09201$138.64 MSRP: $196.26You Save: $57.62 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Water; Engine Water Pump; Water Pump Assembly; Pump Assembly, Engine Water

- Replaces: 16100-09200, 16100-59276, 16100-59275

- Part Name Code: 16100

- Item Weight: 5.80 Pounds

- Item Dimensions: 17.7 x 15.1 x 11.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 16100-09201

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Tundra Water Pump

Looking for affordable OEM 2006 Toyota Tundra Water Pump? Explore our comprehensive catalogue of genuine 2006 Toyota Tundra Water Pump. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Tundra Water Pump Parts Q&A

- Q: How to service and repair the water pump on 2006 Toyota Tundra?A: The service and repair of the water pump should start with removing the engine under cover and draining the engine coolant before proceeding. The service begins when the technician removes V-bank cover and applies light torque to the fan with fluid coupling through the 4 fluid coupling nut adjustments. The service begins with detached V belt from the fan and generator followed by radiator reserve tank hose disconnection then removal of all 4 fan shroud bolts and 4 fluid coupling nuts enabling extraction of the fan with fluid coupling and fan shroud and finally the fan pulley. The technician disconnects hose No.2 and removes air cleaner elements before disconnecting those oil cooler hoses while also removing each radiator and 5 water bypass hoses followed by taking out the water inlet bolts and its O-ring and the water outlet pipe gasket from the water pump. To remove idler pulley No.2 start by removing 2 bolts and 2 idler pulleys then separate the generator with the cooler compressor and remove the V-ribbed belt tensioner before ending with the water pump removal by removing 17 bolts, the water pump and its gasket. Inspection of the water pump must check for coolant leaks at air and water holes while inspecting smooth water pump bearing movement. Replace the water pump if needed. Fortunately check the fluid coupling for damage or silicon oil leaks while planning a necessary replacement if needed. The installation requires using a new gasket together with the water pump which must be secured to the 17 bolts with 9.0 Nm (92 kgf-cm, 80 inch lbs.) torque for 10 mm (0.39 inch) head while using 23 Nm (235 kgf-cm, 17 ft. lbs.) torque for 12 mm (0.47 inch) head. The installation process requires the combination of the V-ribbed belt tensioner assembly with cooler compressor and generator and idler pulley followed by the application of torques to 39 Nm (398 kgf-cm, 29 ft. lbs.) using 2 bolts for securing. Installation of the water inlet requires a new O-ring and gasket along with soapy water application to the O-ring before torquing 5 bolts to 9.0 Nm (92 kgf-cm, 80 inch lbs.). Then establish hose connections for all 5 water by-pass systems and 2 radiator hoses and 2 oil cooler hoses. The air cleaner requires installation with Ventilation Hose No.2 and placement of the fan with fluid coupling on the water pump followed by assembling the fan with fluid coupling and fan shroud along with temporary mounting of the four fluid coupling nuts and tightening four fan shroud bolts to 5.0 Nm (51 kgf-cm, 44 inch lbs.) and connecting the reserve tank hose. The fan assembly process requires installation of the V belt between fan and generator followed by tensioning the fan with fluid coupling through proper torque tightening of all fluid coupling bolts to 21 Nm (214 kgf-cm, 15 ft. lbs.). Then add engine coolant while checking for any fluid leakage. The last phase includes engine cover installation with 4 bolts to 29 Nm torque along with V-bank cover attachment using 2 nuts at 9.8 Nm torque. Then check engine coolant level before filling coolant and starting the engine for leak evaluation followed by a second coolant level check.