×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Prius Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Shock Absorbers found

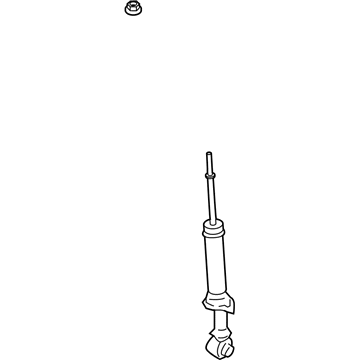

2006 Toyota Prius Shock Absorber, Rear Passenger Side

Part Number: 48530-49715$68.36 MSRP: $95.96You Save: $27.60 (29%)Ships in 1 Business DayProduct Specifications- Other Name: Absorber Set, Rear Right-Hand; Suspension Strut Assembly Kit; Complete Strut Kit; Complete Strut; Strut; Absorber Assembly, Shock, Rear Passenger Side; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48530-47031

- Position: Rear Passenger Side

- Item Weight: 4.30 Pounds

- Item Dimensions: 26.1 x 6.5 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-49715

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

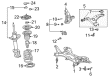

2006 Toyota Prius Strut, Front Driver Side

Part Number: 48520-80081$150.27 MSRP: $212.72You Save: $62.45 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Suspension Strut, Front Left

- Position: Front Driver Side

- Condition: New

- SKU: 48520-80081

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

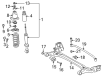

2006 Toyota Prius Strut, Front Passenger Side

Part Number: 48510-80295$151.68 MSRP: $214.72You Save: $63.04 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Suspension Strut, Front Right

- Position: Front Passenger Side

- Condition: New

- SKU: 48510-80295

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Prius Shock Absorber

Looking for affordable OEM 2006 Toyota Prius Shock Absorber? Explore our comprehensive catalogue of genuine 2006 Toyota Prius Shock Absorber. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Prius Shock Absorber Parts Q&A

- Q: How to service and repair the rear shock absorber with coil spring on 2006 Toyota Prius?A: You need to begin servicing and repairing the rear shock absorber with coil spring by taking out the rear No. 2 floor board and several other components which include the rear deck floor box, rear deck trim cover, tonneau cover assembly, rear seatback assembly LH, rear No. 1 floor board, rear side seatback frame LH, rear No. 4 floor board, deck floor box LH, deck trim side panel assembly LH and battery carrier bracket and rear wheel. Begin service and repair of the rear shock absorber with coil spring by securing the rear axle beam to a jack platform while protecting it with wood to prevent damage before removing upper bolts as well as lower nut and spacer. Then safely lower the jack to extract the shock absorber. To separate the components secure the piston rod with a 6 mm socket hexagon wrench before loosening the nut but not removing it. Special Service Tool 09727-30021 (09727-00010, 09727-00021, 09727-00031) reaches the coil spring and enables spring compression until it becomes mobile before the removal of the nut along with the No. 1 cushion washer, No. 1 cushion, rear spring front bracket, rear suspension support, rear coil spring insulator upper, and rear No. 1 spring bumper. Check the LH rear shock absorber assembly for abnormal resistance and sound when the rod is compressed and extended using an inspection process while performing a replacement when needed. Reassembly starts by using Special Service Tool: 09727-30021 to compress the coil spring before fitting its end into the shock absorber lower seat followed by installation of rear coil spring insulator upper, rear No. 1 spring bumper, rear suspension support, rear spring front bracket, and No. 1 cushion and its washer with precise alignment. Complete the tightening procedure of the shock absorber piston rod nut until reaching 56 Nm (571 kgf-cm, 41 ft. lbs.) specifications before releasing the Special Service Tool. First attach the rear shock absorber with coil spring to the rear axle beam while tightening the nut just enough before lifting the beam to position the rear spring front bracket stud bolt within the vehicle. Then apply a torque of 80 Nm (816 kgf-cm, 59 ft. lbs.) when securing the two upper side nuts and bolt to the bracket. Reinstall the rear wheel under 103 Nm (1,050 kgf-cm, 76 ft. lbs.) torque then stabilize the suspension by bouncing the vehicle while performing a full torque up to 80 Nm (816 kgf-cm, 59 ft. lbs.) of the rear shock absorber lower side installation nut after lowering the vehicle. After reattaching the negative (-) battery terminal you must implement initialization since some systems need it and check the rear wheel alignment before reinstalling the battery carrier bracket and deck trim side panel assembly LH together with deck floor box LH, rear No. 4 floor board, rear side seatback frame LH, rear No. 1 floor board, rear seatback assembly LH, tonneau cover assembly, rear deck trim cover, rear deck floor box, and rear No. 2 floor board. Completely extend the shock absorber rod prior to drilling a hole in the cylinder to release gas which requires proper safety equipment because of the present metal shards. When unobserved the gas exists as colorless and odorless and shows no harmful effects.