×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Scion xB Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Alternator found

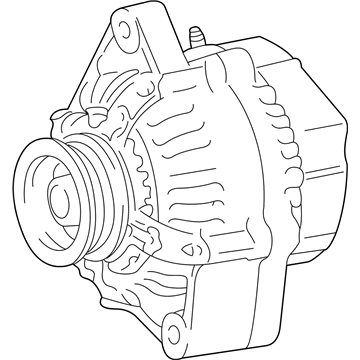

2006 Scion xB Alternator

Part Number: 27060-21020-84$229.12 MSRP: $325.53You Save: $96.41 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Alternator Assembly, With Regulator

- Replaces: 27060-21020

- Item Weight: 16.00 Pounds

- Item Dimensions: 13.5 x 10.8 x 8.9 inches

- Condition: New

- SKU: 27060-21020-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Scion xB Alternator

Looking for affordable OEM 2006 Scion xB Alternator? Explore our comprehensive catalogue of genuine 2006 Scion xB Alternator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Scion xB Alternator Parts Q&A

- Q: How to remove and install an alternator on 2006 Scion xB?A: The process of removing the generator begins with disconnecting the negative cable that controls the battery and waiting for at least 90 seconds to stop Air Bag and seat belt pretensioner activation. Begin generator removal when you detach the terminal cap and unfasten the nut and generator wire before disconnecting the generator connector and releasing the wire harness clamp. Bolts A and B should be loosened first before the generator V-belt tension is released so that the generator V-belt can be removed. The procedure starts by uninstalling bolt A along with the nut and adjusting bar until bolt B and the generator can be removed. The installation process requires temporary bolt attachment of the generator through B and the adjusting bar through A while torquing the nut to 11 N.m (112 kgf.cm, 8 ft.lbf). First attach the generator V-belt on its respective pulley before sliding the adjusting bar between the engine mounting bracket and generator to clear the tension through pushing the bar forward towards the vehicle front. Do not push the bar between the oil control valve and generator as this may result in damage. Tools Operators must tighten bolt A to 18.5 N.m (189 kgf.cm, 14 ft.lbf) and bolt B to 54 N.m (551 kgf.cm, 40 ft.lbf). Affix the clamp to the wire harness and link the generator connector together with the generator wire before tightening the nut to 9.8 N.m (100 kgf.cm, 7 ft.lbf) and then place on the terminal cap. The last step includes both generator V-belt adjustment and connection of the cable to the negative battery terminal.