×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

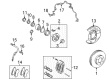

OEM 2004 Toyota Tacoma Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Calipers found

2004 Toyota Tacoma Caliper, Driver Side

Part Number: 47750-04030$264.79 MSRP: $378.07You Save: $113.28 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Position: Driver Side

- Part Name Code: 47750

- Item Weight: 11.30 Pounds

- Item Dimensions: 10.0 x 7.6 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-04030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Tacoma Caliper

Part Number: 47750-04030-84$94.95 MSRP: $131.77You Save: $36.82 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc Brake; Brake Caliper

- Condition: New

- SKU: 47750-04030-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Tacoma Caliper

Part Number: 47730-04030-84$94.95 MSRP: $131.77You Save: $36.82 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assembly, Disc Brake; Brake Caliper

- Condition: New

- SKU: 47730-04030-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

Product Specifications

Product Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Left; Cylinder Assembly, Disc Brake, Driver Side; Brake Caliper

- Manufacturer Note: (L)

- Position: Driver Side

- Replaces: 47750-35100

- Part Name Code: 47750

- Item Weight: 13.70 Pounds

- Item Dimensions: 10.3 x 7.5 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47750-04040

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

Product Specifications

Product Specifications- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Manufacturer Note: (L)

- Position: Passenger Side

- Replaces: 47730-35100

- Part Name Code: 47730

- Item Weight: 12.20 Pounds

- Item Dimensions: 10.0 x 7.8 x 5.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-04040

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc Brake; Brake Caliper

- Condition: New

- SKU: 47750-04040-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc Brake; Brake Caliper

- Condition: New

- SKU: 47730-04040-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Cylinder Assembly, Disc; Disc Brake Caliper, Front Right; Cylinder Assembly, Front Disc Brake, Passenger Side; Brake Caliper

- Position: Passenger Side

- Part Name Code: 47730

- Item Weight: 11.80 Pounds

- Item Dimensions: 10.3 x 7.5 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 47730-04030

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2004 Toyota Tacoma Brake Caliper

Looking for affordable OEM 2004 Toyota Tacoma Brake Caliper? Explore our comprehensive catalogue of genuine 2004 Toyota Tacoma Brake Caliper. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

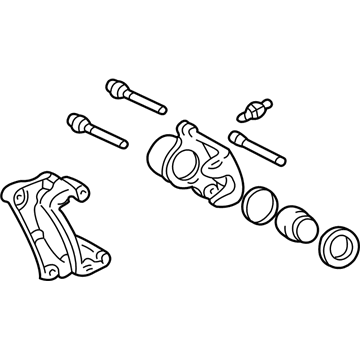

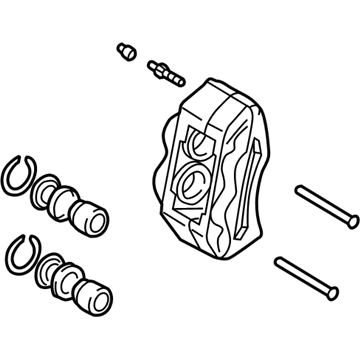

2004 Toyota Tacoma Brake Caliper Parts Q&A

- Q: How to service and repair the front brake caliper on 2004 Toyota Tacoma?A: The front brake caliper service and repair procedure starts with disconnecting the flexible hose through union bolt removal while the hose should remain hanging downward during installation at a torque setting of 30 Nm (310 kgf-cm, 22 ft. lbs.). A contained receptacle must be used to collect any escaping brake fluid. The caliper removal on the torque plate begins with extraction of the two slide pins while applying torque of 88 Nm (900 kgf-cm, 65 ft. lbs.). The service begins by removing both brake pads together with their respective 4 anti-squeal shims and pad wear indicator before taking out the 4 pad support plates. Insert a cloth between the caliper and piston afterward use compressed air to extract the piston and cylinder boot while keeping fingers away from the piston front. The process requires removal of the piston seal with a screwdriver while extracting the sliding bushing and pin boot from the torque plate to properly fit them in the caliper grooves. The pad lining thickness should be measured with a ruler during inspections and the acceptable measurements include 12.0 mm (0.472 inch) standard and 1.0 mm (0.039 inch) minimum. Any pad lining that falls below these minimums requires immediate replacement. The disc measurement with a micrometer must be within the standard range of 22.0 mm (0.866 inch) and minimum of 20.0 mm (0.787 inch) while a repair or replacement occurs when there are scoring, wear or the minimum is reached. Use a dial indicator on the disc edge at 10mm (0.39 inches) distance to measure its runout which must not exceed 0.07mm (0.0028 inches); replace or send for grinding if the measurement is exceeded. To install a new disc first tighten it with 64 Nm torque (650 kgf-cm, 47 ft. lbs.) and put the axle hub and adjusted front bearing preload in place afterward before installing the torque plate with a torque of 108 Nm (1,100 kgf-cm, 80 ft. lbs.). The reassembly process occurs through the sequential steps of disassembly reversal while specific components get greased with lithium soap base glycol grease before every component is put back. During post-installation you should fill brake fluid into the reservoir followed by bleeding the brake system and performing a leak inspection.