×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Highlander Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Starter Motor found

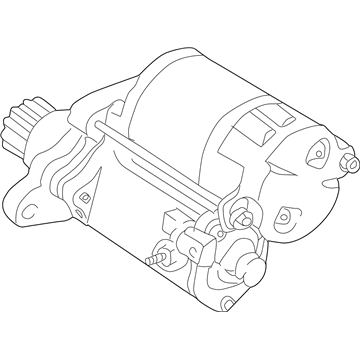

2003 Toyota Highlander Starter Assembly

Part Number: 28100-74260-84$158.04 MSRP: $222.38You Save: $64.34 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: REMAN STARTER ASSY; Starter Motor; Starter

- Replaces: 28100-03100, 28100-74260

- Item Weight: 15.60 Pounds

- Item Dimensions: 13.8 x 6.5 x 6.3 inches

- Condition: New

- SKU: 28100-74260-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Highlander Starter Motor

Looking for affordable OEM 2003 Toyota Highlander Starter Motor? Explore our comprehensive catalogue of genuine 2003 Toyota Highlander Starter Motor. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Highlander Starter Motor Parts Q&A

- Q: How to service and repair the starter motor on 2003 Toyota Highlander?A: Start the starter motor service work by disassembling the starter yoke assembly through these steps: remove the starter cover followed by disconnecting the lead wire from C terminal and unthreading two through bolts to withdraw the field frame assembly and armature together after taking out the O-ring from the starter yoke. You must start by unscrewing 2 screws that detach the magnet starter switch assembly and subsequent removal of starter housing and clutch assembly then you need to pull out the starter magnet switch return spring and starter idle gear pinion and starter idle gear retainer and starter idle gear clutch roller before using a magnetic finger to extract the steel ball from the clutch shaft hole. Then proceed by unscrewing two screws attached to the starter commutator end frame assembly and the end cover from the field frame before retrieving the O-ring from the starter yoke once again. The starter brush holder assembly demands using a screwdriver to maintain the spring while disconnecting brushes from their holder before removing the brush holder. Check the continuity between commutator segments through an ohmmeter test on the starter armature assembly before replacing it. No continuity reading indicates the need for a new armature assembly. Test for continuity between the armature coil core and the commutator after which a new armature assembly needs replacement. To test the circularity of the part use a dial gauge which should show less than 0.05 mm (0.0020 in.) deviation. If the measurement results are higher than 0.05 mm (0.0020 in.) perform corrections on a lathe. The commutator diameter needs a measurement using vernier calipers which must reach at least 29 mm (1.14 in.) or the armature assembly requires replacement. Check the undercut depth for debris while measuring it to be at least 0.2 mm (0.008 in.) because an insufficient depth requires correction with a hacksaw blade. Testing for continuity between field coil brush lead wires and frame should be performed to determine if a replacement of the starter yoke assembly is necessary. Vernier calipers should measure the brush length at least 8.5 mm (0.335 in.) but if it is shorter you must replace the brush holder assembly and starter yoke assembly. A test for continuity between the positive (+) and negative (-) brush holders of the starter brush holder assembly should be performed. Replace this assembly in case continuity is detected. Check the magnet starter switch assembly by testing terminal 50 to C continuity, replace the magnetic switch when no continuity is detected and verify 50-Body continuity, substitute the magnetic switch if no connection is present. Check the starter clutch sub-assembly gear teeth and pinion rotational movement by allowing counterclockwise motion but requiring clockwise locking motion and replace the clutch assembly when necessary. You need to use a brass bar in a vise to disassemble the starter clutch sub-assembly by first placing the starter housing and clutch assembly, pushing down the pinion gear using a plastic faced hammer, extracting the snap ring with a screwdriver, then removing the stop collar and pinion gear and compression spring followed by disassembling the starter housing, starter clutch and clutch shaft and compression spring. The installation sequence begins with assembling the starter housing, starter clutch, compression spring, after which the starter housing and clutch assembly receives mounting on the brass bar while pressing down the starter housing to incorporate the spring retainer, compression spring, pinion gear, and stop collar. As a next step install a new snap ring using snap ring pliers, followed by tapping the clutch shaft to finalize the setup. Fix the starter armature assembly into position after greasing its bearings and placing it within the starter yoke. Start by mounting the starter brush holder assembly onto the starter yoke followed by using a screwdriver to keep the brush spring backward while connecting the brushes with a confirmation of avoiding ground contact to the positive lead wires. Place a new O-ring inside the starter yoke groove before attaching the end frame by screwing it twice and torquing the screws to 1.5 N.m (15 kgf.cm, 13 in.lbf). Perform the following installation steps: place the steel ball in the clutch shaft hole after applying grease and apply grease to the starter magnet switch return spring as well as the starter idle gear pinion, starter idle gear retainer and starter idle gear clutch roller before installing the assembly with 2 screws that require torquing to 5.9 N.m (60 kgf.cm, 52 in.lbf). The last phase includes placing an O-ring in the field frame groove then aligning the magnetic starter switch groove with the starter yoke protrusion while using 2 through bolts to secure and torque to 5.9 N.m (60 kgf.cm, 52 in.lbf). Afterward, wire the C terminal with its nut torqued to 5.9 N.m (60 kgf.cm, 52 in.lbf).