×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

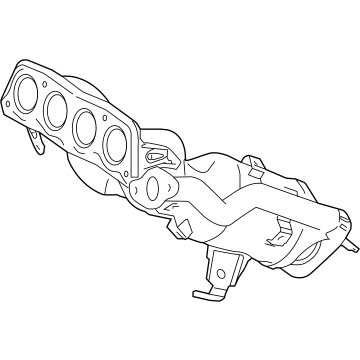

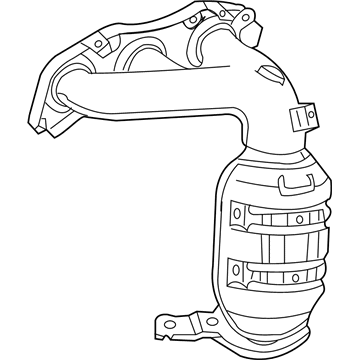

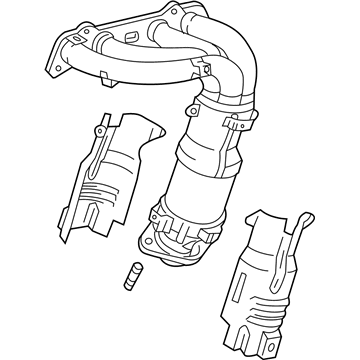

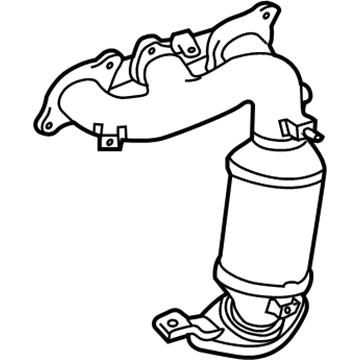

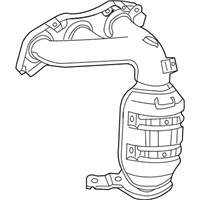

OEM Toyota RAV4 Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Exhaust Manifolds found

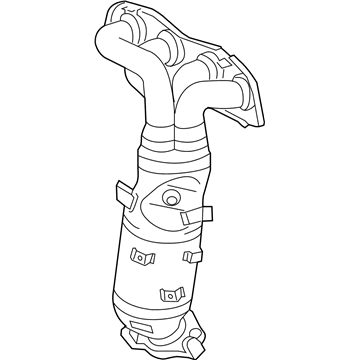

Toyota RAV4 Exhaust Manifold

Part Number: 25051-28260$1019.45 MSRP: $1270.58You Save: $251.13 (20%)Ships in 1-3 Business Days

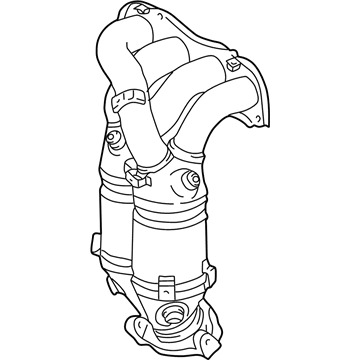

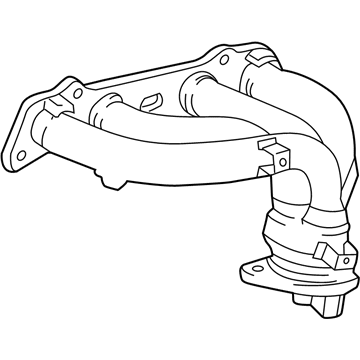

Toyota RAV4 Exhaust Manifold

Part Number: 25051-28340$682.58 MSRP: $850.73You Save: $168.15 (20%)Ships in 1 Business DayToyota RAV4 Exhaust Manifold

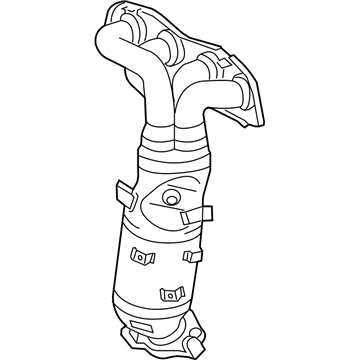

Part Number: 25051-28430$826.72 MSRP: $1030.38You Save: $203.66 (20%)Ships in 1-3 Business DaysToyota RAV4 Exhaust Manifold

Part Number: 17141-F0011$664.30 MSRP: $973.55You Save: $309.25 (32%)Ships in 1-3 Business DaysToyota RAV4 Manifold, Exhaust

Part Number: 17141-F0110$623.67 MSRP: $913.99You Save: $290.32 (32%)Ships in 1-3 Business DaysToyota RAV4 Manifold, Exhaust

Part Number: 17141-F0010$633.32 MSRP: $928.14You Save: $294.82 (32%)Ships in 1-2 Business DaysToyota RAV4 Exhaust Manifold

Part Number: 17141-25330$427.77 MSRP: $626.91You Save: $199.14 (32%)Ships in 1-3 Business DaysToyota RAV4 Exhaust Manifold

Part Number: 17141-25161$826.84 MSRP: $1211.74You Save: $384.90 (32%)Ships in 1-2 Business DaysToyota RAV4 Exhaust Manifold

Part Number: 17141-25150$675.65 MSRP: $990.18You Save: $314.53 (32%)Ships in 1-3 Business DaysToyota RAV4 Exhaust Manifold

Part Number: 17141-25130$744.09 MSRP: $1090.48You Save: $346.39 (32%)Ships in 1-3 Business DaysToyota RAV4 Exhaust Manifold

Part Number: 17141-25021$474.31 MSRP: $695.09You Save: $220.78 (32%)Ships in 1-3 Business DaysToyota RAV4 Exhaust Manifold, Passenger Side

Part Number: 17140-0P110$692.34 MSRP: $1014.64You Save: $322.30 (32%)Ships in 1-3 Business Days

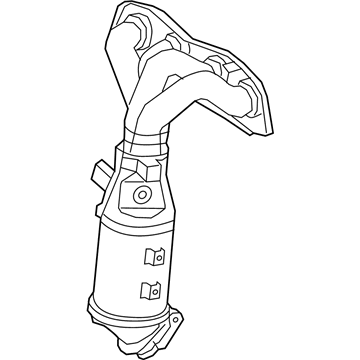

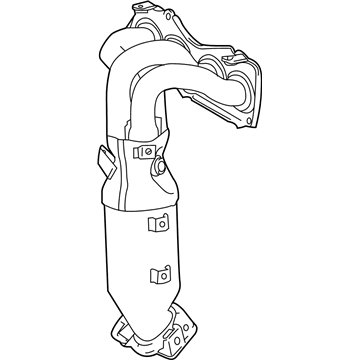

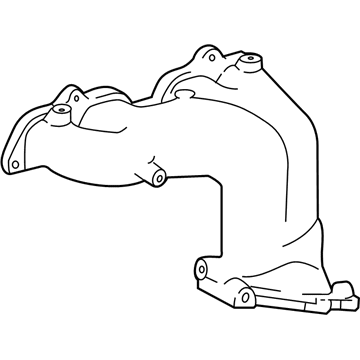

Toyota RAV4 Converter Sub-Assembly, Exhaust Manifold

Part Number: 25051-0V230$454.44 MSRP: $566.39You Save: $111.95 (20%)

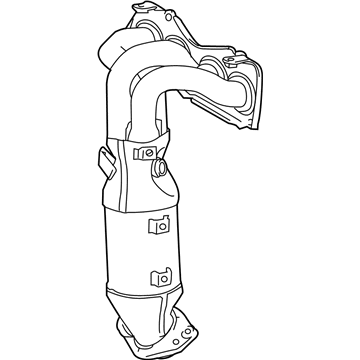

Toyota RAV4 Exhaust Manifold, Driver Side

Part Number: 17150-0P090$1002.87 MSRP: $1469.72You Save: $466.85 (32%)

Toyota RAV4 Exhaust Manifold

Choose genuine Exhaust Manifold that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Exhaust Manifold for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 Exhaust Manifold Parts and Q&A

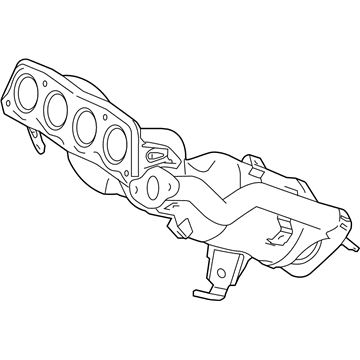

- Q: How to install the exhaust manifold on Toyota RAV4?A:The installation of an exhaust manifold begins with installing the No. 1 manifold converter insulator that requires 4 bolts with 12 Nm (122 kgf-cm, 9 ft-lbf) torque. Place a new gasket onto the cylinder head while installing the exhaust manifold converter temporarily using 5 nuts that need to be tightened in the specified sequence to 35 Nm (357 kgf-cm, 26 ft-lbf). You should start with No. 2 exhaust manifold heat insulator installation using two bolts that require 12 Nm torque (122 kgf-cm or 9 ft-lbf) before adding four bolts to the No. 1 exhaust manifold heat insulator at the same torque rate. Coat the No. 2 manifold stay with a bolt along with a nut that requires 43 Nm (438 kgf-cm, 32 ft-lbf) torque followed by another bolt using a nut torqued at the same strength. Integrate the air fuel ratio sensor (for Bank 1 Sensor 1) along with the radiator hose clamp as well as the engine oil level dipstick guide and the engine oil level dipstick. When inspecting the front Exhaust Pipe compression spring with a vernier caliper check its free length surpasses 41.5 mm (1.63 in.) otherwise replace the component. The surface requires cleaning with a wire brush before adding new gaskets that face the exhaust manifold converter while maintaining its correct position yet eliminating the use of any old gaskets. A fresh gasket follows to cover the front exhaust pipe's surface. Use 2 compression springs and 4 bolts to mount the front exhaust pipe along with torqueing bolt A and bolt B at 43 Nm pressure (438 kgf-cm, 32 ft-lbf). Finally, connect the heated oxygen sensor connector. Complete the task by setting up the generator assembly while checking for exhaust gas leaks throughout the system.

- Q: How to remove the exhaust manifold on Toyota RAV4?A:The removal process for an exhaust manifold on a 2AR-FE engine requires the generator assembly as the first step. The removal procedure begins with disconnected heated oxygen sensor and bolted-out 4 fasteners which results in removing both front Exhaust Pipe and two compression springs and exhaust manifold converter gaskets. The maintenance requires extraction of both the engine oil level dipstick and its guide. The radiator hose clamp requires uninstallation before moving forward. During the replacement process remove the air fuel ratio sensor from its location for Bank 1 Sensor 1. You begin with step one which includes removing the manifold stay by uninstalling its bolt along with nut and stay until completion of the first step. Step two follows to perform the process on the No. 2 manifold stay with identical procedures. You need to take out the 4 bolts of the No. 1 exhaust manifold heat insulator before you can remove the No. 2 exhaust manifold heat insulator by removing its 2 bolts. The procedure requires removing the 5 nuts in sequence from the exhaust manifold converter sub-assembly and afterwards removing the converter and gasket before removing the No. 1 manifold converter insulator using its bolts and insulator.