×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2008 Toyota Sienna Fuel Pressure Regulator

Fuel Tank Pressure Regulator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Fuel Pressure Regulator found

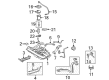

2008 Toyota Sienna Damper Assembly, Fuel Pressure Pulsation

Part Number: 23270-31140$111.14 MSRP: $156.01You Save: $44.87 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Fuel Pressure Damper; Fuel Pump Pulsator

- Replaces: 23270-31080, 23270-31010

- Part Name Code: 23270

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.0 x 2.3 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 23270-31140

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2008 Toyota Sienna Fuel Pressure Regulator

Looking for affordable OEM 2008 Toyota Sienna Fuel Pressure Regulator? Explore our comprehensive catalogue of genuine 2008 Toyota Sienna Fuel Pressure Regulator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2008 Toyota Sienna Fuel Pressure Regulator Parts Q&A

- Q: How to install the fuel pressure regulator and related components on 2008 Toyota Sienna?A: Begin the fuel pressure pulsation damper installation by applying spindle oil or gasoline to a new O-ring before installing it to the damper. You should install the fuel pressure pulsation damper onto the fuel delivery pipe by using the clip to fasten it. The installer should progress by putting together the intake air surge tank assembly and completing the installation of the air cleaner cap sub-assembly. The engine must receive coolant before you can put the cable onto the negative battery terminal. Maintenance personnel need to check for coolant leakage before installing the No. 1 engine under cover. A complete examination for fuel leaks must occur before the V-bank cover sub-assembly installation takes place. Together the aircraft must receive the cowl top panel sub-assembly outer front component followed by the No. 1 cowl top to cowl brace inner, windshield wiper motor and link assembly while receiving the front wiper arm LH and RH.