×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2006 Toyota Avalon Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Alternators found

2006 Toyota Avalon Alternator

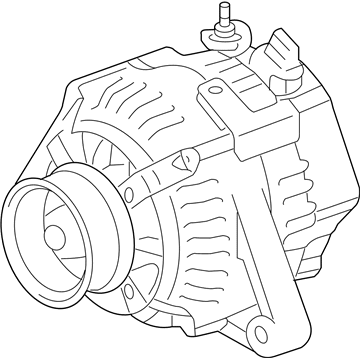

Part Number: 27060-0P151-84$254.50 MSRP: $339.22You Save: $84.72 (25%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Reman Alternator

- Replaces: 27060-0P150, 27060-0P151

- Item Weight: 13.50 Pounds

- Item Dimensions: 13.6 x 10.9 x 9.1 inches

- Condition: New

- SKU: 27060-0P151-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Avalon Reman Alternator

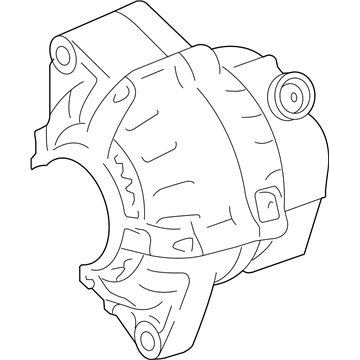

Part Number: 27060-0P141-84$315.46 MSRP: $420.98You Save: $105.52 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Alternator

- Replaces: 27060-0P141, 27060-0P140

- Item Weight: 14.60 Pounds

- Item Dimensions: 9.6 x 8.2 x 7.5 inches

- Condition: New

- SKU: 27060-0P141-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2006 Toyota Avalon Alternator

Looking for affordable OEM 2006 Toyota Avalon Alternator? Explore our comprehensive catalogue of genuine 2006 Toyota Avalon Alternator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2006 Toyota Avalon Alternator Parts Q&A

- Q: How to overhaul the alternator on 2006 Toyota Avalon?A: Begin the alternator overhaul process by eliminating the generator with clutch pulley while using a screwdriver to detach the generator pulley cap and inserting SST (A) and (B) equipped with SST 09820-63020 to position the rotor shaft onto SST (A) before securing it in a vise. Install the generator using the SST while you rotate SST (B) clockwise to loosen the generator pulley thus removing both components from SST and the rotor shaft. Afterward you should remove 3 nuts prior to removing the generator rear end cover along with the terminal insulator. To access the generator brush holder assembly the technician must remove the two screws before they can take off the generator coil assembly through four bolts with SST 09950-40011 (09951-04020, 09952-04010, 09953-04020, 09954-04010, 09955-04071, 09957-04010, 09958-04011) tool followed by the removal of the generator washer. Remove all parts from the generator rotor assembly. Check that the clutch pulley of the generator turns counterclockwise only without experiencing clockwise rotation. Use vernier calipers to measure the exposed brush length of the generator brush holder assembly and verify that the length satisfies 10.5 mm (0.413 in.) and exceeds 4.5 mm (0.177 in.) and if not replace with a new part. DEL will inspect the generator rotor assembly bearing for irregularities or wear and will replace it if essential and will test the slip ring resistance at 20 degrees Celsius with an ohmmeter to check it stays between 2.3 to 2.7 Ohms; any results failing will require replacement. To check for short circuits perform two tests: measure the 1 MOhm or higher resistance between each slip ring and rotor and determine the slip ring diameter falls between 14.2 to 14.4 mm (0.559 to 0.567 in.) with a minimum of 14.0 mm (0.551 in.). Replacement is needed if minimums are not met. Check for wear or roughness on the drive end frame bearing of the generator and replace it as needed. The bearing removal process for the generator drive end frame requires the removal of bearing retainer screws and SST utility with 09950-60010 (09951-00250) and 09950-70010 (09951-07100) for tapping it out using an SST hammer. To put in a new generator drive end frame bearing, begin by inserting it with SST 09950-60010 (09951-00470) and 09950-70010 (09951-07100) while using a press tool. Finish with bearing retainer installation through the use of 4 screws that should be torqued to 2.3 N.m (23 kgf.cm, 20 in.lbf). Slowly push the generator coil assembly into the drive end frame structure with a deep 21 mm socket wrench which should be activated by a press tool to secure it through four bolt screws torqued up to 5.8 N.m (59 kgf.cm, 51 in.lbf). The generator brush holder assembly requires two brush compressions followed by a 1.0 mm (0.039 in.) pin insertion into the generator brush holder hole. The next step is to install both screws at 1.8 N.m (18 kgf.cm, 16 in.lbf) while keeping the pin in position until it is removed. The terminal insulator requires proper orientation before you install it and then you can add the rear end cover with the three nuts torqued to 4.6 N.m (47 kgf.cm, 41 in.lbf). Utilize SST (A) and (B) for this step while positioning SST (A) in the vise to start installation of the generator on the SST. Rotate SST (B) clockwise until the generator pulley reaches 87 N.m (891 kgf.cm or 64 ft.lbf) using a torque wrench set at 380 mm (14.96 in.). After generator removal from the SST inspections must demonstrate smooth generator pulley rotation and the new generator pulley cap must be installed.