×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2005 Toyota Solara Exhaust Pipe

Exhaust Tail Pipe- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Exhaust Pipes found

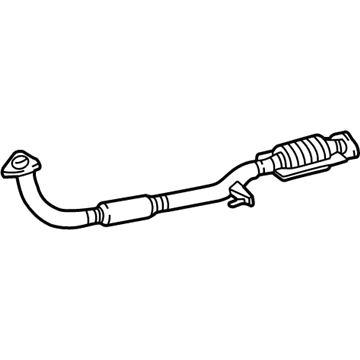

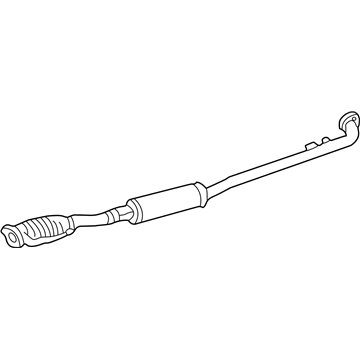

2005 Toyota Solara Front Pipe

Part Number: 17410-0H150$1125.45 MSRP: $1510.69You Save: $385.24 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Converter & Pipe; Pipe Assembly, Exhaust, Front

- Manufacturer Note: (L)

- Position: Front

- Replaces: 17410-0H090

- Part Name Code: 17410

- Item Weight: 11.60 Pounds

- Item Dimensions: 48.6 x 18.2 x 9.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17410-0H150

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

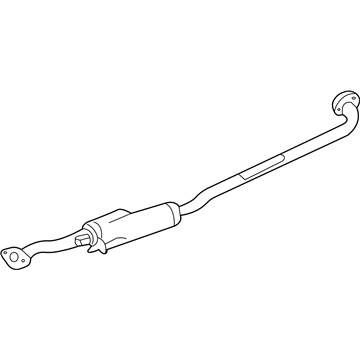

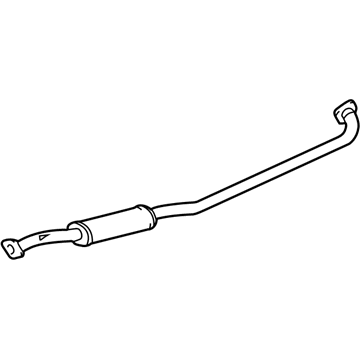

2005 Toyota Solara Center Pipe

Part Number: 17420-0A300$372.84 MSRP: $500.45You Save: $127.61 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Intermediate Pipe; Exhaust Pipe; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 17.50 Pounds

- Item Dimensions: 52.9 x 19.8 x 9.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0A300

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota Solara Intermed Pipe, Center

Part Number: 17420-0A290$323.63 MSRP: $423.21You Save: $99.58 (24%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Intermediate Pipe; Exhaust Pipe; Center Pipe; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 17.40 Pounds

- Item Dimensions: 50.4 x 20.4 x 9.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0A290

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota Solara Intermed Pipe, Center

Part Number: 17420-0H010$343.43 MSRP: $449.11You Save: $105.68 (24%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Intermediate Pipe; Exhaust Pipe; Direct-Fit Exhaust; Exhaust System Kit; Center Pipe; Pipe Assembly, Exhaust, Center

- Position: Center

- Part Name Code: 17420

- Item Weight: 17.40 Pounds

- Item Dimensions: 50.4 x 19.8 x 9.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-0H010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

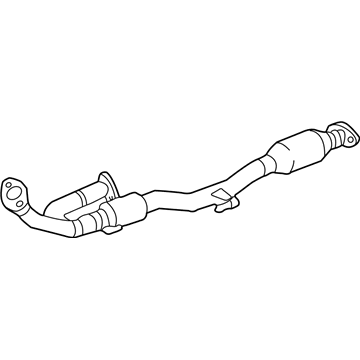

2005 Toyota Solara Front Pipe

Part Number: 17410-0A370$1477.42 MSRP: $1983.12You Save: $505.70 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Converter & Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

- Part Name Code: 17410

- Item Weight: 7.30 Pounds

- Item Dimensions: 30.2 x 2.3 x 19.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17410-0A370

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

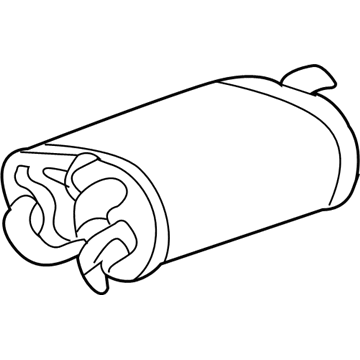

2005 Toyota Solara Muffler W/Tpipe

Part Number: 17430-0A261$505.86 MSRP: $679.01You Save: $173.15 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Tail; Exhaust Muffler; Direct-Fit Exhaust; Exhaust System Kit; Exhaust Pipe; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Tail

- Replaces: 17430-0A260

- Part Name Code: 17430

- Item Weight: 10.20 Pounds

- Item Dimensions: 43.6 x 12.2 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17430-0A261

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota Solara Muffler W/Tpipe

Part Number: 17430-0H121$474.08 MSRP: $636.35You Save: $162.27 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Tail; Exhaust Muffler; Exhaust Muffler Assembly; Exhaust Pipe; Tail Pipe; Muffler; Pipe Assembly, Exhaust, Tail

- Replaces: 17430-0H120

- Part Name Code: 17430

- Item Weight: 10.40 Pounds

- Item Dimensions: 44.4 x 12.3 x 8.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17430-0H121

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2005 Toyota Solara Exhaust Pipe

Looking for affordable OEM 2005 Toyota Solara Exhaust Pipe? Explore our comprehensive catalogue of genuine 2005 Toyota Solara Exhaust Pipe. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2005 Toyota Solara Exhaust Pipe Parts Q&A

- Q: How to replace the exhaust pipe assembly (except PZEV) on 2005 Toyota Solara?A: The exhaust pipe assembly (except PZEV) replacement process starts by checking for old gaskets along with rusted bolts and nuts to be removed first. The first step requires you to remove both floor panel brace rear bolts along with the bolts from the floor panel brace rear. The next step involves removing the exhaust pipe damper through the removal of its 2 bolts. The exhaust pipe front requires removal of two bolts and two nuts before extracting the pipe center from its two exhaust pipe supports. Remove the heated oxygen sensor (bank 1 sensor 2) along with its disconnect. Start by discarding the front exhaust pipe No. 1 support bracket after unfastening both nuts then proceed with removing the rear exhaust pipe No. 1 support bracket when all two bolts are undone. Detach the exhaust pipe front by taking off both nuts and pipe front before removing the tail pipe from three exhaust pipe supports. A plastic hammer should be used to hit the tail pipe baffle uniformly for removal purposes. To install the tail pipe baffle correctly position the keyway into the key location on the pipe before tapping it secure. Fitting of the exhaust pipe assembly tail must be done by attaching the 3 exhaust pipe supports before joining the exhaust pipe assembly front to the exhaust manifold converter using 2 nuts that require torque to 62 Nm (632 kgf-cm, 46 ft. lbs.). First, place the rear support bracket with two bolts that need a torque setting of 33 Nm (337 kgf-cm, 24 ft. lbs.) while ensuring the bracket points in the correct direction. After that, install the front support bracket using two nuts torqued at 33 Nm (337 kgf-cm, 24 ft. lbs.). Position the heated oxygen sensor (bank 1 sensor 2) to the pipe front area before tightening it to 44 Nm (449 kgf-cm, 32 ft. lbs.) and reconnecting its connector. The exhaust pipe assembly center requires two bolts and two nuts for connecting new gasket sections at the pipe front with torque set to 56 Nm (571 kgf-cm, 41 ft. lbs.). The same gasket installation procedure applies to the pipe tail area with two nuts. Connect the exhaust pipe damper by torquing two bolts to 19 Nm (194 kgf-cm, 14 ft. lbs.) while putting the facing side in the proper direction followed by attaching the floor panel brace rear with two bolts torqued to 19.5 Nm (199 kgf-cm, 14 ft. lbs.). Exhaust gas leak tests must be completed before tightening vulnerable areas that need repair with new replacement parts.