×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Tacoma Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Axle Shafts found

2003 Toyota Tacoma Axle Shaft, Rear

Part Number: 42311-35350$439.91 MSRP: $644.70You Save: $204.79 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts; Shaft, Rear Axle, Passenger Side; Shaft, Rear Axle, Driver Side

- Manufacturer Note: W(4WHEEL*66)

- Position: Rear

- Item Weight: 23.30 Pounds

- Item Dimensions: 26.3 x 23.2 x 23.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 42311-35350

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Axle Shaft, Rear

Part Number: 42311-35380$424.48 MSRP: $622.08You Save: $197.60 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts

- Position: Rear

- Part Name Code: 42311

- Item Weight: 15.10 Pounds

- Item Dimensions: 29.3 x 7.7 x 6.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 42311-35380

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

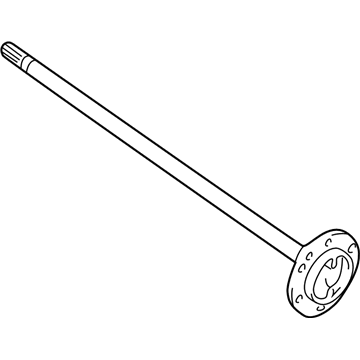

2003 Toyota Tacoma Axle Shaft, Rear

Part Number: 42311-35340$437.53 MSRP: $641.21You Save: $203.68 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts

- Position: Rear

- Part Name Code: 42311

- Item Weight: 15.10 Pounds

- Item Dimensions: 29.3 x 7.7 x 6.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 42311-35340

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Axle Shaft, Rear

Part Number: 42311-35370$385.12 MSRP: $564.39You Save: $179.27 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts

- Manufacturer Note: W(4WHEEL*66)

- Position: Rear

- Part Name Code: 42311

- Item Weight: 14.40 Pounds

- Item Dimensions: 30.1 x 7.5 x 7.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 42311-35370

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

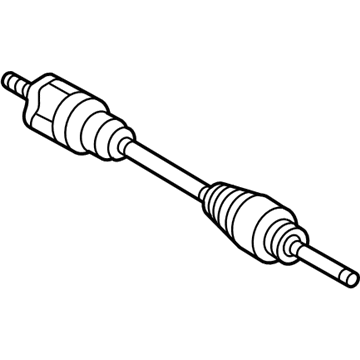

2003 Toyota Tacoma Axle Assembly, Front

Part Number: 43430-04020$413.31 MSRP: $605.71You Save: $192.40 (32%)Product Specifications- Other Name: Shaft Assembly, Front Drive; CV Axle Assembly, Front Left, Front Right; GSP Cv Axle; Axle Shaft; Shaft Assembly, Front Drive, Passenger Side; Shaft Assembly, Front Drive, Driver Side; CV Axle Assembly

- Manufacturer Note: W(A.D.D)

- Position: Front

- Item Weight: 23.50 Pounds

- Item Dimensions: 36.4 x 6.1 x 6.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 43430-04020

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts

- Manufacturer Note: W(4WHEEL*66)

- Position: Rear

- Part Name Code: 42311

- Item Weight: 15.10 Pounds

- Item Dimensions: 30.4 x 7.7 x 6.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 42311-35390

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Shaft, Rear Axle; Drive Axle Shaft, Rear; Axle Shafts

- Position: Rear

- Part Name Code: 42311

- Item Weight: 14.40 Pounds

- Item Dimensions: 29.6 x 7.8 x 6.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 42311-35360

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Tacoma Axle Shaft

Looking for affordable OEM 2003 Toyota Tacoma Axle Shaft? Explore our comprehensive catalogue of genuine 2003 Toyota Tacoma Axle Shaft. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

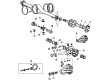

2003 Toyota Tacoma Axle Shaft Parts Q&A

- Q: How to service and repair the axle shaft on 2003 Toyota Tacoma?A: The first step of servicing and repairing the axle shaft starts with wheel and brake drum removal while maintaining 110 Nm (1,150 kgf-cm or 83 ft. lbs.) torque. Test the axle shaft deviation using a dial indicator on both components because axle shaft deviation should not exceed 0.1 mm (0.0039 inch) and bearing backlash should not surpass 0.7 mm (0.028 inch). If these values exceed the specifications, discard the damaged components. The ABS speed sensor connected to the rear axle housing should be taken out when servicing this combination of components while securing it with an 8.0 Nm (82 kgf-cm, 71 inch lbs.) torque. The rear brake assembly removal starts with 2WD before using Special Service Tool: 09751-36011 to disconnect the brake line at 15 Nm (155 kgf-cm, 11 ft. lbs.) torque followed by removing two bolts securing the parking brake cable at 9.3 Nm (95 kgf-cm, 82 inch lbs.). To remove the rear axle shaft assembly start by removing the four backing plate mounting nuts at 68 Nm torque using a torque wrench then slowly extract the assembly keeping away from the oil seal. The rear axle housing O-ring removal step precedes bearing retainer and ABS speed sensor rotor detachment by hitting the serration bolts when using a hammer and avoiding use of already removed nuts. Using a grinder, modify the surfaces of both retainer and sensor rotor before putting back the serration bolts to the backing plate. A snap ring expander should be used to remove the snap ring from the axle shaft before pressing out the rear axle shaft and bearing retainer from the backing plate with Special Service Tool: 09521-25011. To inspect the axle shaft and flange runout the maximum accepted values are 2.0 mm (0.079 inch) for the shaft while 0.1 mm (0.004 inch) stands as the maximum for the flange. The shaft requires replacement whenever it shows signs of damage or if the runout exceeds the specified limits. Use Special Service Tool: 09308-00010 to remove the outer oil seal before installing the rear axle bearing through Special Service Tools 09223-56010, 09950-60010 (09951-00560) and a press. Complete the installation with Special Service Tools: 09515-30010, 09950-60020 (09951-00890) and a press. Utilize Special Service Tool: 09950-60010 (09951-00610), 09950-70010 (09951-07150) together with a hammer for installing a new outer oil seal. The bearing case requires replacement after the removal of both bearing and outer oil seal through which new parts must be installed with a hammer to secure serration bolts and bearing case. To replace the oil deflector you must first separate the hub bolts from the deflector alongside its gasket using a hammer and brass bar. Install new components by placing the gasket and hub bolts on their respective positions. Install the rear axle shaft by putting it into the backing plate after coating the new oil seal lip with MP grease while using Special Service Tool: 09316-60011 (09316-00051) and a press for mounting the shaft. To install a new snap ring use a snap ring expander then for ABS models fit the ABS speed sensor rotor and bearing retainer through Special Service Tool: 09316-60011 (09316-00051) and a press until the standard length reaches 122.2 plus or minus 1.0 mm (4.811 plus or minus 0.039 inch). Follow the procedures for replacing the inner oil seal with Special Service Tool: 09308-00010 while you will use Special Service Tool: 09950-60020 (09951-00710) and 09950-70010 (09951-07150) with a hammer to install a new oil seal after coating its lip in MP grease. The entire process of installation follows the reverse order of removal. When finished install the system bleed the brake system then verify the ABS speed sensor signal.