×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2003 Toyota Avalon Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Alternator found

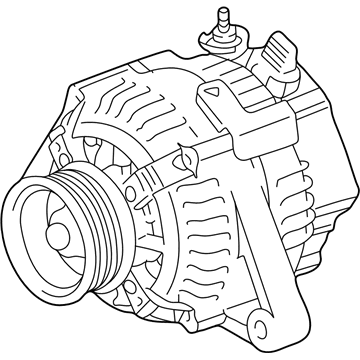

2003 Toyota Avalon Alternator

Part Number: 27060-0A050-84$264.52 MSRP: $352.66You Save: $88.14 (25%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Reman Alternator 1Mz

- Item Weight: 15.90 Pounds

- Item Dimensions: 9.5 x 7.4 x 8.2 inches

- Condition: New

- SKU: 27060-0A050-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2003 Toyota Avalon Alternator

Looking for affordable OEM 2003 Toyota Avalon Alternator? Explore our comprehensive catalogue of genuine 2003 Toyota Avalon Alternator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2003 Toyota Avalon Alternator Parts Q&A

- Q: How to service and repair the alternator on 2003 Toyota Avalon?A: Service and repair of the alternator requires first removing the drive belt by loosening three bolts: Pivot bolt at 56 N.m along with adjustment lock bolt at 18 N.m and adjusting bolt at 56 N.m. These bolts correspond to torque values of 570 kgf.cm for the Pivot bolt and 180 kgf.cm for the adjustment lock bolt. Lastly, the belt can be removed using the adjusting bolt torque of 180 kgf.cm. The next step requires you to disconnect the generator connector followed by loosening the nut to take off the generator wire at 9.8 N.m (100 kgf.cm, 86 in.lbf) torque while taking the wire harness off the clip. The procedure ends with the removal of the pivot bolt together with the plate washer and adjusting lock bolt and the generator. During installation you should do the operations in the opposite order of removal procedures.