×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota Solara Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Water Pumps found

Product Specifications

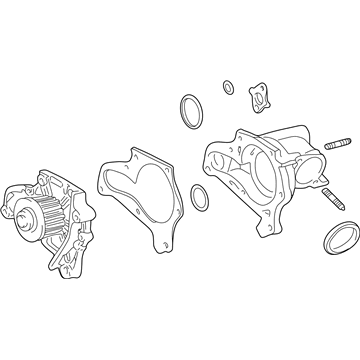

Product Specifications- Other Name: Water Pump Assembly; Engine Water Pump Assembly; Engine Water Pump

- Replaces: 16100-09040, 16100-79186, 16100-09041, 16100-79075, 16100-79075-84, 16100-79185, 16100-79075-77

- Item Weight: 4.80 Pounds

- Item Dimensions: 8.6 x 6.7 x 6.3 inches

- Condition: New

- SKU: 16100-79185-83

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Solara Water Pump

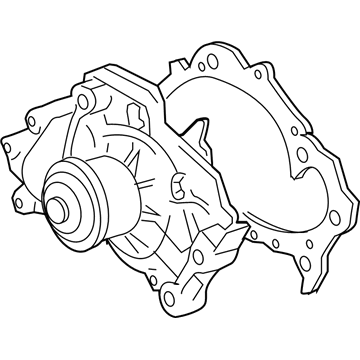

Part Number: 16100-29085$75.09 MSRP: $105.41You Save: $30.32 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Water; Engine Water Pump; Water Pump Assembly; Pump Assembly, Engine Water

- Replaces: 16100-09070

- Part Name Code: 16100

- Item Weight: 2.50 Pounds

- Item Dimensions: 10.0 x 6.5 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 16100-29085

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota Solara Water Pump

Looking for affordable OEM 2000 Toyota Solara Water Pump? Explore our comprehensive catalogue of genuine 2000 Toyota Solara Water Pump. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota Solara Water Pump Parts Q&A

- Q: How to service and repair the water pump on 2000 Toyota Solara?A: Service technical work on the water pump begins with draining engine coolant followed by taking off the suspension upper brace and timing belt and camshaft timing pulleys and No.2 idler pulley and No.3 timing belt cover. The water pump removal process begins by unscrewing its four bolts and two nuts while also extracting the components with their gasket. Visual inspection of the water pump should reveal coolant leakage from its drain hole. In case of leakage you must replace the water pump. The pump replacement becomes necessary if the pulley turn reveals that the bearing function shows signs of noise or immobility. Check all parts that make up the timing belt components during inspection. To install the water pump as a new gasket and pump need to be placed in position while using the 4 bolts and 2 nuts tightened to 6 Nm (60 kgf-cm, 53 inch lb.) while avoiding oil contact with the gasket. You should now proceed to install the ceiling signal and timing chain and its pulleys along with the idler pulley and timing belt cover. The suspension upper brace should finish up your sequence by getting the four nuts torqued to 80 Nm (820 kgf-cm, 59 ft. lbs.). Proceed by pouring engine coolant inside the system before starting the engine to detect any leaks and inspecting the engine coolant quantity one more time.