×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2000 Toyota MR2 Spyder Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Shock Absorbers found

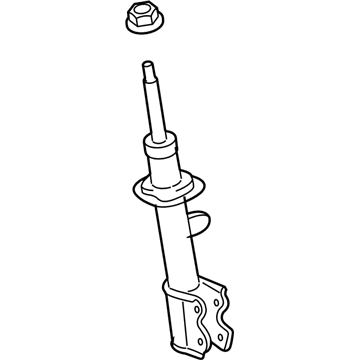

2000 Toyota MR2 Spyder Strut, Rear Driver Side

Part Number: 48540-19375$149.33 MSRP: $211.39You Save: $62.06 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Suspension Strut, Rear Left; Shock Absorber; Absorber Assembly, Shock, Rear Driver Side

- Manufacturer Note: MARK 48540-17230

- Position: Rear Driver Side

- Replaces: 48540-19366, 48540-19365

- Part Name Code: 48540

- Item Weight: 6.50 Pounds

- Item Dimensions: 26.4 x 6.6 x 5.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48540-19375

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota MR2 Spyder Strut, Rear Passenger Side

Part Number: 48530-80078$142.75 MSRP: $202.08You Save: $59.33 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber Assembly, Shock; Suspension Strut, Rear Right; Shock Absorber; Absorber Assembly, Shock, Rear Passenger Side

- Manufacturer Note: MARK 48530-17230

- Position: Rear Passenger Side

- Replaces: 48530-80027, 48530-80060

- Part Name Code: 48530

- Item Weight: 6.90 Pounds

- Item Dimensions: 25.6 x 6.6 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 48530-80078

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2000 Toyota MR2 Spyder Shock Absorber

Looking for affordable OEM 2000 Toyota MR2 Spyder Shock Absorber? Explore our comprehensive catalogue of genuine 2000 Toyota MR2 Spyder Shock Absorber. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2000 Toyota MR2 Spyder Shock Absorber Parts Q&A

- Q: How to service and repair the Shock Absorber on 2000 Toyota MR2 Spyder?A: Start suspension strut service and repair by using Special Service Tool: 09727-30021 (09727-00010, 09727-00021, 09727-00031) to compress the coil spring while avoiding damage to the tool with an impact wrench. Begin by removing the screwdriver from the spring seat before unscrewing the nut while keeping close watch on the spring seat to avoid damage. Then proceed to remove the suspension support together with the dust seal and spring seat and upper insulator and coil spring and spring bumper. To inspect the shock absorber, compress the rod until it extends for checking irregular resistance or odd sounds then change the shock absorber if any problems occur. Disposal of shock absorbers requires rod extension before drilling a cylinder hole to release the gas with caution on chip potential and awareness that the gas has no color and odor and presents no harm to human health. Reassembly begins with attaching the spring bumper to the piston rod. After this step use the same special service tool to compressed the coil spring before finally mounting the shock absorber with the lower end resting within the spring lower seat gap. The installation process starts with the upper insulator followed by spring seat placement then requires alignment of piston rod notch and spring seat hole before adding the dust seal and suspension support. A screwdriver should be used to maintain suspension support stability as you install a new nut before it receives 51 Nm (520 kgf-cm, 38 ft. lbs.) torque while paying attention to spring seat integrity. End the process by removing the special service tool followed by MP grease application to the suspension support and cap installation.