×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2001 Toyota Echo Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Alternators found

2001 Toyota Echo Alternator

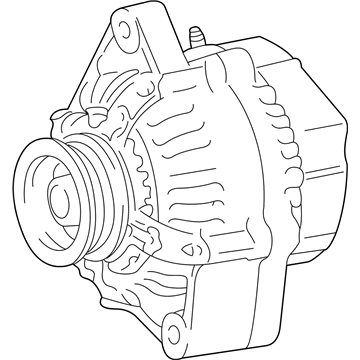

Part Number: 27060-21020-84$229.12 MSRP: $325.53You Save: $96.41 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Alternator Assembly, With Regulator

- Replaces: 27060-21020

- Item Weight: 16.00 Pounds

- Item Dimensions: 13.5 x 10.8 x 8.9 inches

- Condition: New

- SKU: 27060-21020-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Item Weight: 12.70 Pounds

- Condition: New

- SKU: 27060-21041-84

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2001 Toyota Echo Alternator

Looking for affordable OEM 2001 Toyota Echo Alternator? Explore our comprehensive catalogue of genuine 2001 Toyota Echo Alternator. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2001 Toyota Echo Alternator Parts Q&A

- Q: How to service and repair the alternator on 2001 Toyota Echo?A: Start the alternator servicing procedure by disassembling the unit: first separate the rear end cover by unfastening the nut followed by the terminal insulator and finally the bolt and 3 nuts and plate terminal and end cover. Start by taking off the seal plate from the rectifier end frame followed by the voltage regulator and brush holder through the brush holder cover and its 5 screws. The rectifier holder requires 4 screw removal followed by the holder itself accompanied by a removal of all 4 rubber insulators. Use Special Service Tool 09820-63010 to remove the pulley by applying torque to the socket clockwise to 39 Nm (400 kgf.cm, 29 ft.lbf) while maintaining the tool on the rotor shaft. Place the adapter into a vise while inserting the socket and attaching the pulley nut to the vise but loosen it by counterclockwise rotation of the tool and prevent excessive half-turn motion to safeguard the rotor shaft integrity. The generator removal process begins when the adapter loses contact with the pulley and socket holding tool before removing the pulley nut and pulley. Start by detaching the rectifier end frame through a four-nut and wire-clip removal process before applying Special Service Tool 09286-46011 to release the frame while you also remove the generator washer from the rotor. Reassembly starts by fastening the rotor to the drive end frame through pulley-mounting of the rectifier end frame followed by rotor attachment. Using the provided 29 mm socket wrench combine with press operation to decisively install the rectifier end frame by using the wire clip and 4 nuts to fix the assembly with Nut A torqued to 4.5 N.m (46 kgf.cm, 40 in.lbf) and Nut B torqued to 5.4 N.m (55 kgf.cm, 48 in.lbf). Hand-tighten the pulley nut before using the pulley holding tool connected to a torque wrench to achieve a clockwise torque of 39 N.m (400 kg.cm or 29 ft.lb) and keep the tool securely attached to the pulley shaft. After torquing the pulley nut to 111 N.m (1,132 kg.cm, 82 ft.lb), remove the generator from the adapter before unfastening the socket and tool. Secure the rectifier holder by placing 4 rubber insulators on lead wires correctly then fasten it with 4 screws that require 2.9 N.m (30 kgf.cm, 26 in.lbf) torque. Following correct installation direction, install the five screws for the voltage regulator and brush holder to the rectifier end frame and torque them to 2.0 N.m (20 kgf.cm, 18 in.lbf). Place the end cover properly and plate terminal together using bolt and three nuts followed by torqueing the Nut to 4.4 N.m (45 kgf.cm, 39 in.lbf) and Bolt to 3.9 N.m (39 kgf.cm, 35 in.lbf). Afterward, add the terminal insulator with the nut then torque it to 4.1 N.m (42 kgf.cm, 36 in.lbf) before testing rotor smooth rotation.